ISO 9001:2015 Certified

ISO 9001:2015 Certified

CE Certified

CE Certified

ANSI Certified

ANSI Certified

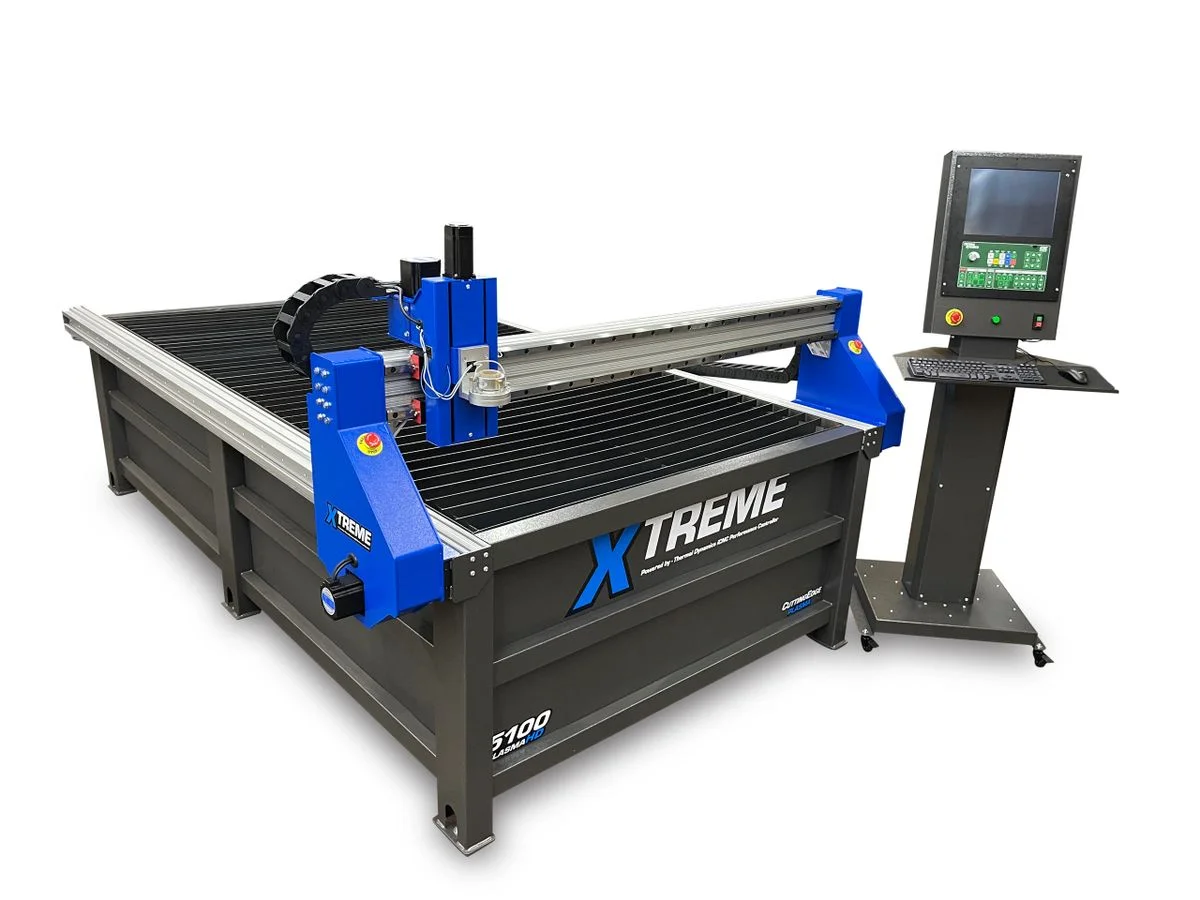

Professional Industrial Cutting & Machining Equipment Solutions

Discover our comprehensive range of advanced CNC plasma tables, routers, sanders, and plasma cutting systems designed for precision industrial fabrication. From automated plasma cutting to sophisticated routing and finishing solutions, our equipment delivers exceptional performance for metalworking, woodworking, and manufacturing applications. Each machine features robust construction, advanced control systems, and precision-engineered components for reliable operation in demanding industrial environments.