A router table does far more than hold a router, it directly affects how smoothly your woodworking shop completes shaping, trimming, and joinery tasks. Even the best rated router table requires thoughtful selection to maintain accurate cuts, steady workflow, and predictable project outcomes.

When the table isn’t built well or the setup doesn’t match your workload, you may see uneven edges, repeated corrections, slower output, and unnecessary material loss. Knowing what influences performance and how each component contributes to your results helps you maintain consistency across every project.

This guide breaks down the top best rated router table options for 2026, explaining their features, pricing, and ideal applications.

Key Takeaways

A router table directly impacts how smoothly woodworking shops handle shaping, trimming, and joinery tasks, supporting cleaner cuts and steady workflow.

Matching table size, frame strength, and fence adjustability to your shop’s workload ensures efficient, hassle-free operation every day.

Features like dust collection, stable bases, and easy bit-height control reduce errors, protect tools, and keep projects on schedule.

Comparing tables based on shop size, project demands, and upgrade options helps you choose a model that works for both current needs and future growth.

Investing in a reliable, user-friendly table, like those supported by Cutting Edge Plasma, minimizes downtime, simplifies maintenance, and keeps production consistent.

Why the Best Rated Router Table Matters for Woodworking Shops?

Woodworking shops deal with constant routing tasks whether you’re shaping cabinet doors, trimming solid wood panels, creating grooves, or finishing decorative edges. In busy workshops, even small issues like vibration, dust buildup, or difficult adjustments can slow production and affect finish quality.

This is why many teams prefer using the best rated router table that keeps cuts steady, setups simple, and daily routing predictable.

To support day-to-day operations, the best rated router tables for Woodworking Shops usually offer a mix of features that keep the workflow smooth and consistent.

Here’s what woodworking shops generally rely on:

Stable, Vibration-Free Base: A firm base keeps the router steady during edge profiling, dado cuts, and joinery work so you get cleaner results across hardwoods and composites.

Smooth Fence Adjustment: Easy fence movement helps you switch between straight cuts, pattern shaping, and fine joinery without wasting time on constant readjustments.

Strong Dust Collection Port: Good chip extraction keeps the surface clean, improves visibility, and reduces bit wear during long routing sessions.

Large, Flat Work Surface: A spacious top supports wide cabinet panels, long moulding strips, and small custom pieces with equal stability.

Easy Bit-Height Control: Quick height changes help you handle multi-pass cuts, deep profiles, and delicate shaping work with better accuracy.

Durable Insert Plate: A sturdy insert plate keeps the router locked in place during heavy routing, helping you avoid uneven cuts or tool shifts.

User-Friendly Safety Features: Guard systems and featherboards help operators work confidently while maintaining control through detailed routing tasks.

And preparing for higher workloads ensures smooth operations and steady output. Models such as the PRO Series from Cutting Edge Plasma are built for shops aiming for long-term reliability and growth.

Why This Helps Your Woodworking Shop:

A dependable best rated router table supports smoother routing, fewer adjustments, and more consistent output.

For woodworking shops where performance and cleanliness matter every day, the right table helps maintain quality, reduce rework, and keep your team focused on production instead of troubleshooting.

With these benefits in mind, now look at the top-rated options for small and professional woodworking shops.

Top 8 Router Tables for Woodworking Shops & Professionals

When it comes to running a woodworking shop efficiently, having the right router table can make all the difference. From handling larger panels to supporting daily production without hiccups, the right table balances stability, versatility, and ease of use.

Here’s a curated selection of the best tables, balancing build quality, versatility, and affordability.

Model | Price | Best / Ideal For |

$17,995 | Large shops needing a wide cutting area, steady performance, and reliable operation for daily workloads | |

$16,995 | Small–mid-size shops needing fast, reliable cutting for high-volume production | |

$17,495 | Medium–large shops needing fast cutting with long-term reliability | |

Bosch RA1181 Benchtop Router Table | Budget-friendly (varies) | Woodworkers needing a compact, dependable benchtop router table |

Kreg PRS1045 Freestanding Router Table | Mid-range professional | Woodworkers needing a strong, stable setup for demanding shop work |

Rockler Convertible Benchtop Router Table | Budget-friendly (varies) | Small shops or mobile woodworkers needing portability and flexibility |

Ryobi Intermediate Router Table | Budget-friendly (varies) | DIYers and small shops wanting a router table compatible with most routers |

Dremel 231 Shaper Router Table (Mini) | Budget compact | Hobbyists and small workspaces needing a portable mini router table |

Below, we’ve compiled the 8 best rated router tables for woodworking shops and professionals, highlighting options that suit everything from compact home setups to full-scale fabrication environments.

1. Lockwood PRO 5100 CNC Router

Price: $17,995

Best for: Shops that need a large cutting area, steady performance, and reliable operation for demanding daily workloads

Why It Stands Out:

The Lockwood PRO 5100 CNC Router is designed for shops that take on bigger projects and need a machine that stays stable during long production hours.

Its fully welded, powder-coated frame keeps vibrations low, helping you achieve clean cuts across wood, plastics, and non-ferrous materials.

The 3 HP air-cooled spindle is built for continuous use, and the machine’s motion system supports smooth travel even when handling heavy sheets.

If your workflow involves switching between multiple tools, the optional pneumatic auto tool changer helps speed up job transitions and reduces downtime.

Perfect For:

Fabricators who want a spacious working envelope without sacrificing day-to-day ease of use.

If you’re planning to handle larger panels, maintain steady production, and keep your operations running efficiently, the Lockwood PRO 5100 offers the durability and working room needed for growing workloads.

2. Lockwood PRO 4400 CNC Router

Price: $16,995

Best for: Small to mid-size fabrication shops needing accuracy, speed, and reliability for high-volume production

Why It Stands Out:

The Lockwood PRO 4400 is built to deliver dependable performance throughout the day, thanks to its solid steel frame and stable motion system.

Its 3 HP air-cooled spindle handles a wide range of materials without struggle, making it useful for wood, plastics, and light metal tasks.

With 8" of Z-axis travel, you can work with thicker stock comfortably. For shops that need smoother workflow and quicker tool changes, the optional 6 HP pneumatic ATC spindle adds an efficient upgrade.

Perfect For:

Workshops that want a sturdy, easy-to-operate router that supports increasing workloads without introducing complexity. If your goal is to maintain consistent output, take on more projects comfortably, and rely on a machine that performs day after day, the Lockwood PRO 4400 fits well into a growing shop’s workflow.

3. Lockwood PRO 4800 CNC Router

Price: $17,495

Best for: Medium to large fabrication shops that need fast, accurate cutting with reliable, long-term performance

Why It Stands Out:

The Lockwood PRO 4800 CNC Router includes a solid welded steel frame keeps the machine steady during long work hours, and the smooth-motion system helps you achieve clean, reliable cuts across different materials.

The 3 HP air-cooled spindle supports demanding workloads, while the 8" Z-axis travel allows you to work with thicker material without limitations.

Optional upgrades like the pneumatic automatic tool changer help you switch tools quickly, saving time on every job and improving workflow efficiency.

Perfect For:

Shops that want to increase output without adding complexity to their workflow. If you’re planning to take on larger projects, reduce manual adjustments, and keep production moving steadily, the Lockwood PRO 4800 gives you the capacity and dependability needed to grow confidently.

4. Bosch RA1181: Versatile Benchtop Option

Price: Varies by retailer (typically budget-friendly)

Ideal For: Woodworkers who want a compact, dependable router table that adapts easily to different tasks.

Why It Stands Out:

The aluminum-steel construction keeps the table steady while you work, helping you get cleaner, smoother results. Its adjustable fence makes setup quick, and the expandable layout lets you tailor the table for different projects.

From edge shaping to joinery, the RA1181 supports a wide range of woodworking needs without complicating your workflow.

Perfect For:

Anyone looking for a flexible, easy-to-manage router table for furniture building, general woodworking, and medium-volume tasks. If you want a stable, no-nonsense table that fits comfortably into small shops or home workshops, the RA1181 is a dependable choice.

5. Kreg PRS1045: Professional Freestanding System

Price: Varies by retailer (mid-range professional category)

Ideal For: Woodworkers who want a solid, dependable setup for demanding shop work.

Why It Stands Out:

The PRS1045 uses a heavy-duty freestanding frame that helps reduce vibration, giving you steadier control during detailed cuts.

Its spacious MDF tabletop provides plenty of room for larger pieces, while the height-adjustable fence allows you to fine-tune each pass with confidence.

Whether you’re shaping edges or fitting joinery, the system supports accurate, smooth performance throughout long work sessions.

Perfect For:

Shops focused on building custom cabinets, detailed furniture, and work that requires careful control. If you want a router table that stays stable under pressure and helps you handle delicate tasks without fuss, the PRS1045 fits seamlessly into a professional workflow.

6. Rockler Convertible Benchtop: Portable and Flexible

Price: Budget-friendly, varies by retailer

Ideal For: Woodworkers or small shops that need a setup they can move, store, or reposition easily.

Why It Stands Out:

Its convertible design lets you switch between a stable benchtop station and a portable table whenever the project demands it.

The built-in dust collection port helps keep your workspace cleaner, making it easier to focus on the task without constant cleanup.

This flexibility makes it especially useful for makers who don’t have the space for a full-size, fixed router table.

Perfect For:

Anyone handling mobile woodworking projects, tight workshops, or multipurpose spaces. If you need a router table that adapts quickly and doesn’t take up permanent room, this model fits smoothly into a compact, on-the-go workflow.

7. Ryobi Intermediate Router Table

Price: Budget-friendly, depending on retailer

Ideal For: DIYers and small workshops that want a router table that works well with most routers.

Why It Stands Out:

The Ryobi Intermediate Router Table is designed to be a versatile fit for a wide range of router models, making it a convenient option if you already own a router or plan to switch tools over time.

Its sturdy tabletop provides steady support for everyday cuts, while the adjustable fence helps you stay consistent across different projects.

The built-in accessory slots and simple setup make it easy to adapt as your projects change.

Perfect For:

Home users, hobby woodworkers, and light shop tasks where flexibility matters. If you want a table that installs quickly, works with nearly any router, and keeps your workflow simple without overwhelming features, this Ryobi model is a dependable universal choice.

8. Dremel 231 Shaper Router Table

Price: Budget-friendly compact option

Ideal For: Hobbyists, DIY users, and small workspaces where portability matters.

Why It Stands Out:

This mini router table attaches easily to most Dremel rotary tools, giving you a stable surface for light shaping, sanding, and trimming tasks.

Its compact design makes it simple to store, move, or set up quickly, and the adjustable platform provides better control than handheld use.

Even with its small size, it offers enough stability for detailed craft work and small project finishing.

Perfect For:

Anyone working on small-scale projects like model making, crafts, trimming edges, or light woodworking. If you need a compact, easy-to-use setup that helps you handle delicate tasks without taking up shop space, the Dremel 231 fits perfectly into a beginner or hobby workshop.

And choosing the right table starts with knowing which features directly affect workflow, efficiency, and output quality.

How to Choose the Right Router Table for Your Woodworking Shop?

A router table influences how efficiently your woodworking shop handles shaping, trimming, and joinery work. The right setup supports steady output, fewer corrections, and a cleaner workflow.

When you bring a router table into your production environment, it should help your team work with confidence instead of slowing them down.

Here are the factors that matter most for daily shop use.

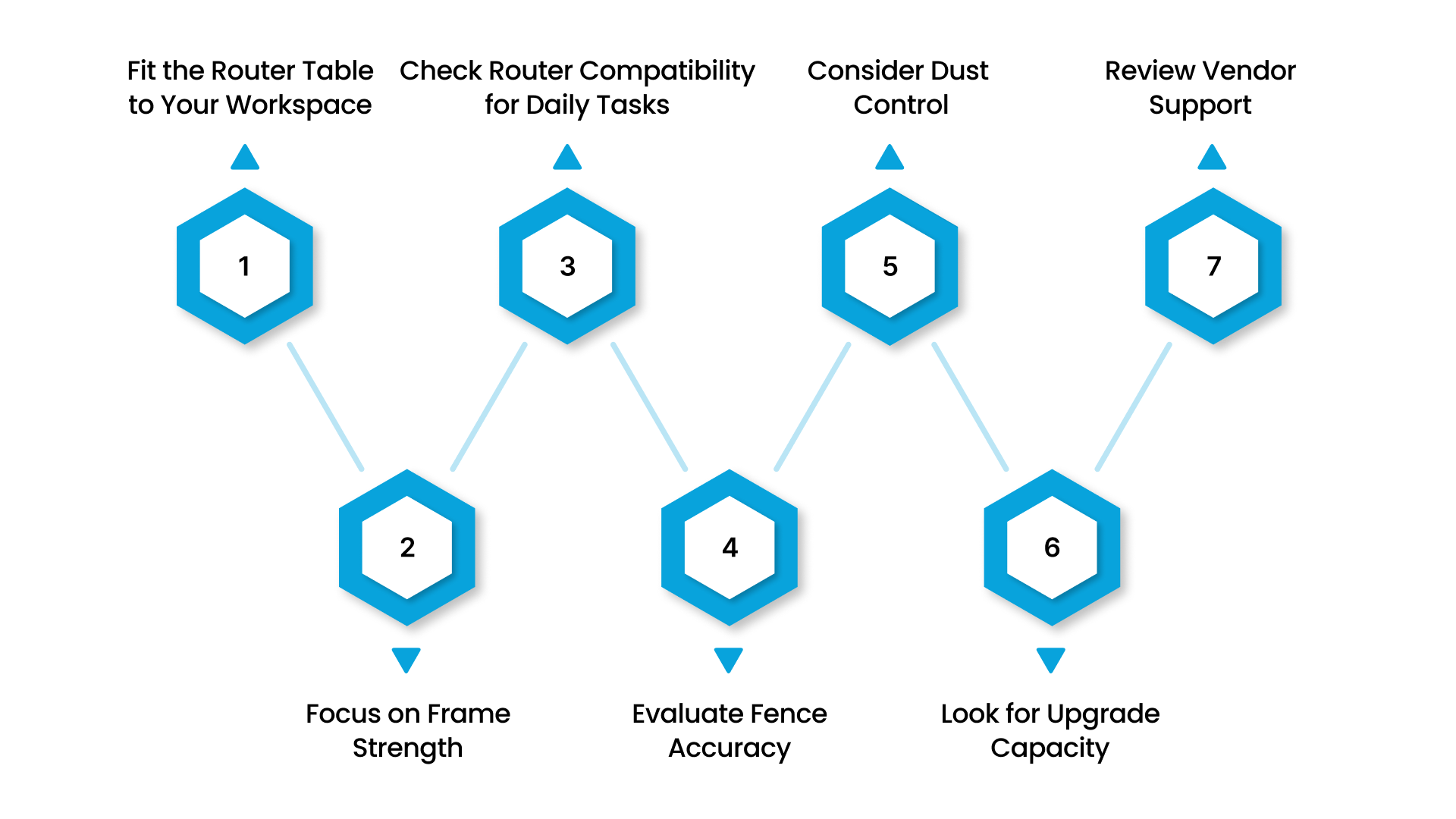

1. Fit the Router Table to Your Workspace

Choosing a router table, such as Lockwood PRO 5100, Lockwood PRO 4800, Lockwood PRO 4400 starts with confirming how well it fits your current layout, because operators need room to move long boards, rotate panels, and load materials without obstruction.

A table that fits the available space keeps handling smoothly, reduces unnecessary repositioning, and improves safety during continuous work.

2. Focus on Frame Strength and Surface Stability

A rigid frame and steady surface matter when your team performs shaping, trimming, and joinery tasks.

Strong construction limits vibration, maintains alignment, and supports cleaner passes during long runs. This reduces the chance of repeated cuts and keeps the overall output predictable.

3. Check Router Compatibility for Daily Tasks

The table should securely support the fixed-base or plunge routers your shop already uses.

Proper mounting keeps the router stable during deeper cuts, prevents shifting during detailed work, and allows operators to transition between tasks without delays caused by re-setup time.

4. Evaluate Fence Accuracy and Adjustability

A reliable fence influences every cut. Smooth micro-adjustments help maintain accurate lines, clean profiles, and repeatable results across batches. A perfect wall reduces the number of trial passes and supports consistent performance, whether you’re shaping edges or doing joinery.

5. Consider Dust Control and Maintenance Requirements

Effective dust extraction keeps surfaces clear, improves visibility, and reduces cleanup time at the end of each shift.

Cleaner operation also protects moving parts and helps maintain consistent performance across repeated workloads.

6. Look for Upgrade Capacity

If your shop handles a mix of custom orders, cabinets, and production work, consider whether the table supports extensions, lifts, or advanced routing accessories.

Expandability lets you handle more complex assemblies without having to replace the entire system later.

7. Review Vendor Support and Warranty Strength

Good vendor support simplifies troubleshooting, especially for teams without dedicated maintenance staff. With Cutting Edge Plasma's clear warranty terms and direct access to replacement parts, you can resolve issues faster, reduce downtime, and keep production on schedule.

Beyond the router table itself, the proper support and guidance can keep your shop running smoothly and reduce downtime.

How Cutting Edge Plasma Supports Woodworking Shops with Router Tables?

If your workshop handles custom wood projects, furniture making, or small-scale production, having the proper router table setup is crucial for smooth workflow, accurate cuts, and reduced material waste.

The proper guidance helps you maintain clean workspaces, minimize errors, and keep daily operations predictable, and Cutting Edge Plasma delivers practical support, clear instructions, and hands-on tips that woodworking teams rely on every day.

Here’s why woodworking shops and small teams turn to Cutting Edge Plasma:

Space-Efficient Design: Compact tables fit smaller workshops while still handling custom cuts, joinery, and small production runs without crowding the workspace.

Adjustable Fence and Height Control: Built-in height adjustments keep the router bit at the ideal distance from the material. This protects bits, reduces mistakes, and ensures cleaner cuts for shops managing multiple projects.

Dust Collection for Cleaner Work: Integrated dust ports and table design reduce debris, making daily cleanup easier and protecting equipment from damage.

Budget-Friendly Ownership: Durable components and innovative design make these tables a practical choice for small to growing shops, keeping costs predictable without compromising quality.

Anti-Kickback and Safety Features: Safety mechanisms prevent accidents during tricky cuts or corners, helping newer operators work confidently and consistently.

Simple, Intuitive Operation: User-friendly controls make setup and daily use straightforward, ideal for shops where one person manages multiple jobs.

Reliable Support Structure: Clear warranty coverage and access to expert support help shops resolve issues quickly without a dedicated maintenance staff.

Why does this matter for your woodworking shop?

The best router table setup is one that delivers consistent cuts, clean operation, and reliable workflow. These features help woodworking shops maintain steady output, reduce mistakes, and make daily operations easier for every team member.

Conclusion

The best rated router table helps woodworking shops complete projects more smoothly, maintain accurate cuts, and operate safely. A quality table improves workflow, reduces material waste, and allows teams to focus on high-value craftsmanship.

Comparing the best rated router tables with guidance from Cutting Edge Plasma gives your shop the insight needed to balance durability, performance, and cost.

For guidance on features, setup, or maintenance, you can reach out to Cutting Edge Plasma to get detailed information and ensure your shop invests in the right table for steady, reliable operation.

FAQs

1. What makes the best router table for woodworking shops?

The best router table delivers stability, accurate cuts, and smooth operation with minimal effort. Look for a rigid frame, quality fence, and smooth lift system to support accurate, consistent work.

2. How do I choose between freestanding and benchtop router tables?

Freestanding tables offer larger surfaces and greater stability, while benchtop tables provide portability and fit smaller workspaces. Match your choice to your shop size and project demands.

3. Which features are most important for precision work?

Adjustable fences, modular table surfaces, smooth lift mechanisms, and sturdy construction are key. These features help maintain accuracy and reduce errors in detailed projects.

4. How does table size affect woodworking workflow?

A properly sized table allows easy handling of materials, minimizes mistakes, and keeps projects moving efficiently. Compact tables work for small shops, while larger tables suit bigger panels or complex assemblies.

5. Is a higher-priced router table always worth it?

Not always. Focus on durability, essential features, and workflow compatibility rather than just the price. A well-matched table ensures efficiency without overspending.