Cutting aluminum on a CNC router can deliver impressive results, but only when the right techniques, tools, and settings are in place.

Unlike wood or plastics, aluminum demands precise control of feeds, speeds, chip evacuation, and cutter selection to avoid broken bits, poor finishes, or heat buildup. With the right approach, your CNC machine can produce clean, accurate cuts and long tool life.

This guide breaks down the most important tips and techniques to help you machine aluminum safely, efficiently, and with professional-grade results.

Key Takeaways

Use carbide end mills with a low flute count (one or two) to maximise chip evacuation space and minimise heat-induced material welding.

Always calculate and maintain the correct chip load. Avoid a feed rate that is too slow, as this causes the tool to rub the aluminium, leading to overheating and rapid dulling.

Use multiple, shallow passes instead of deep cuts to manage heat, reduce tool strain, and ensure optimal chip evacuation.

Implement an air blast or mist system to cool the cut zone and actively clear chips away, which is critical for preventing built-up edge (BUE) formation.

Phase 1: Tool Selection and Geometry

The quality of your CNC cut aluminum parts starts with choosing the correct end mill. Selecting the wrong tool is the fastest route to premature wear and failure.

1. Choose Carbide Cutters for Superior Performance

When cutting aluminum with a router, carbide tools are non-negotiable. They are the best choice for this application.

Carbide can withstand the higher temperatures generated when machining aluminium, unlike High-Speed Steel (HSS).

The material’s hardness allows it to run at the high Revolutions Per Minute (RPM) needed for aluminium, reducing machining time and boosting productivity.

Investing in high-quality carbide end mills ensures greater durability and tool longevity, which reduces overall operating costs.

2. Use Cutters with Fewer Flutes

Aluminium chips are soft and large, and they tend to clog the flutes of the cutter quickly. Clogging causes friction, heat, and eventually, tool breakage.

Opt for single-flute or two-flute end mills, and rarely a three-flute bit.

Fewer flutes create larger, deeper channels (flute pockets), which allow the aluminium chips to escape easily.

This efficient chip evacuation prevents the material from re-welding onto the cutter, a common issue known as Built-Up Edge (BUE).

3. Select Appropriate Cutter Coatings

For high-volume CNC router aluminum work, a specialized coating can dramatically improve performance.

Look for coatings like ZrN (Zirconium Nitride) or DLC (Diamond-Like Carbon).

These coatings create a highly slick, polished surface on the flute.

This smoothness reduces friction and prevents the soft aluminium from sticking to and welding onto the cutter's edge.

Once you have the right tool, the next critical element is optimising how that tool interacts with the material.

Phase 2: Optimising Feeds, Speeds, and Passes

Achieving a clean CNC cut aluminum finish requires finding the ‘sweet spot’ between spindle speed (RPM) and feed rate (the linear speed of the tool). This is often referred to as the chip load.

4. Master Your Feeds and Speeds (Chip Load)

The right chip load ensures the cutter slices the material rather than rubbing it, which prevents heat build-up and tool wear.

Spindle Speed (RPM): Aluminium generally requires high spindle speeds, often 10,000 RPM or higher, but this depends on your machine’s capability and tool diameter.

Feed Rate: If your feed rate is too slow relative to the RPM, the tool will rub, generating excessive heat and a poor finish.

Use a Calculator: Always use a reputable online feeds and speeds calculator to determine the optimal starting values based on your specific alloy (like CNC router cutting aluminium 6061), cutter diameter, and number of flutes.

Target Chip Load: For aluminium, the recommended chip load is very small, often between 0.02mm and 0.08mm per tooth.

5. Make Multiple Shallow Passes

Do not attempt to rout half-inch aluminum 1 pass; this places massive stress on the tool and generates excessive heat, virtually guaranteeing a broken bit or a poor finish.

Reduce Depth of Cut: Adopt a shallow Depth of Cut (DOC), typically set to a maximum of half the cutter diameter (e.g., 3mm DOC for a 6mm cutter).

Benefits: Multiple shallow passes significantly reduce the heat load on the tool and the material, improving chip evacuation efficiency.

This conservative approach is far easier on the machine, extends tool longevity, and produces a far superior surface finish.

6. Implement Trochoidal Milling Techniques

For deep slots or internal pockets, trochoidal milling is a highly effective tool path strategy that prolongs tool life.

Definition: Trochoidal milling involves moving the cutter in a small, continuous circular or helical path while simultaneously moving forward.

Benefit: This approach keeps the tool engaged for a shorter period, reduces the width of the cut, and ensures the entire length of the cutting edge is utilised.

The reduced friction and heat generation make it ideal for CNC router aluminum projects where heat management is critical.

The final phase of cutting aluminium focuses on the mechanical and chemical support systems: clamping, cooling, and safety.

Phase 3: Workholding, Cooling, and Chip Management

Even with perfect speeds and feeds, if heat is not controlled or the chips are not removed, the cutter will quickly fail.

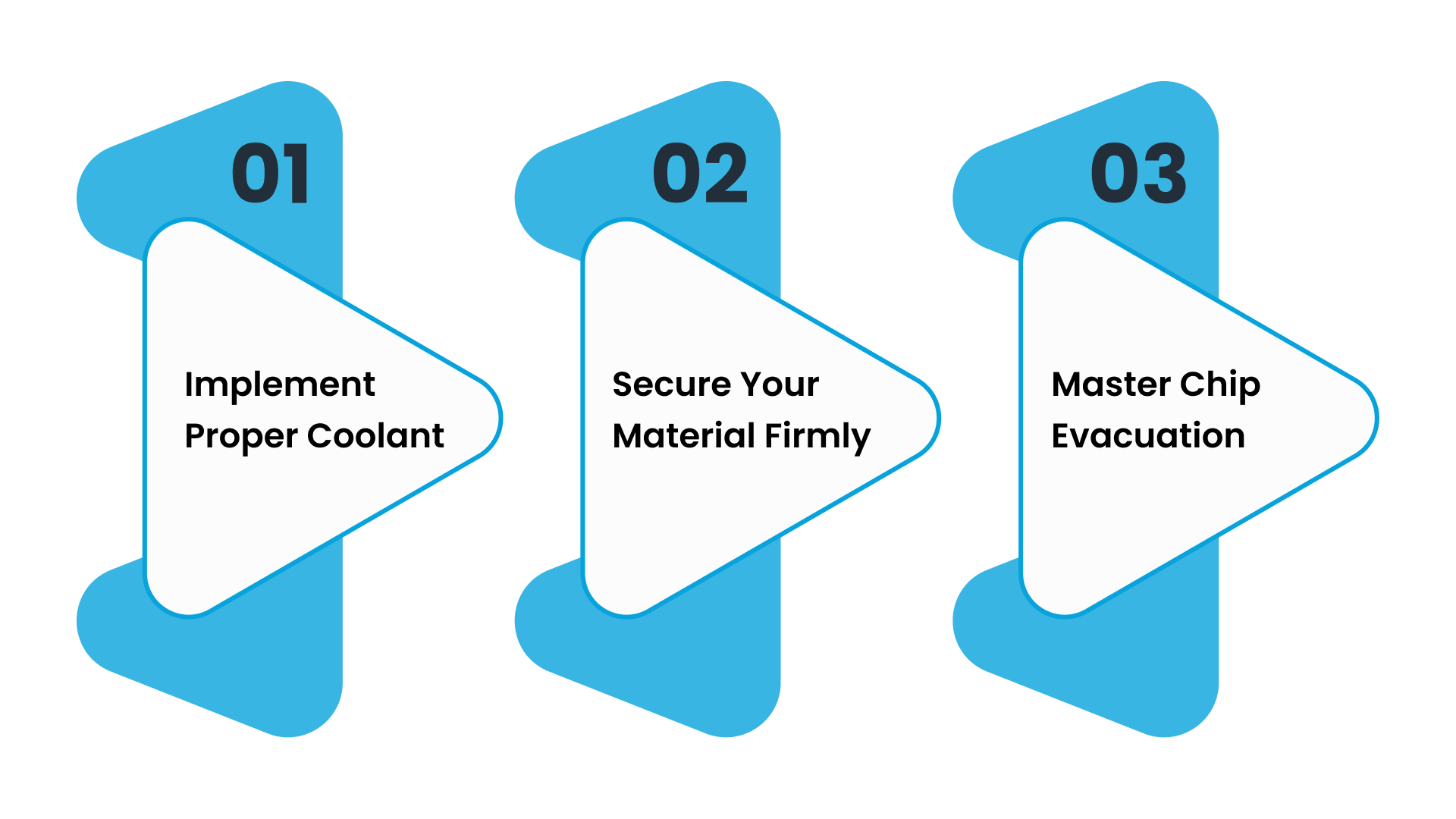

7. Implement Proper Coolant and Lubrication Systems

Heat is the primary enemy of CNC router cutting aluminium 6061 and other alloys, as it causes the metal to soften and stick to the tool.

Misting/Air Blast: A quality system using a coolant mist or a simple air blast is essential. The blast of air not only helps cool the material but, more importantly, clears chips from the cutting zone.

Lubrication: Applying a specialised cutting fluid or lubricant, often via a micro-drop mister, prevents the material from welding to the cutter. Isopropyl alcohol can also be used effectively for this purpose.

Avoid Dry Cutting: Never attempt deep or prolonged cuts in aluminium without active cooling and lubrication.

8. Secure Your Material Firmly (Fixturing)

Aluminium is soft and can flex or vibrate easily under cutting pressure, which leads to chatter and a poor surface finish.

Vacuum Tables: For thin sheets used in CNC router sign making aluminum sheet, a strong vacuum table hold-down is highly effective, distributing the force evenly across the surface.

Clamping: Use sturdy clamps around the perimeter and ensure the entire workpiece is fully supported beneath the cut line to prevent bending or warping during machining.

A rigid workspace is necessary for precision; any movement will increase heat and degrade the cut quality.

9. Master Chip Evacuation and Management

Effective chip evacuation is arguably the most important operational consideration when cutting aluminium.

Air Flow: Use a powerful air blast or a chip blower directed at the cutter. This forces the hot chips out of the cut path immediately.

Consequences of Poor Evacuation: Allowing chips to accumulate causes recutting, which drastically increases friction, leading to rapid tool wear and the formation of BUE.

Conclusion

Successfully executing CNC router aluminum cutting hinges on preparation and attention to detail. By moving away from settings used for wood and plastic and adopting a disciplined approach to tooling (using carbide and a few flutes), precise speed and feed rates (calculated for correct chip load), and aggressive chip management (cooling and air blast), you can consistently achieve the highest quality results.

Remember, slower, shallower passes are always preferable to a single aggressive cut when working with metal. Follow these tips to maximise tool life and unlock the full potential of your CNC router for aluminium fabrication.

Take your aluminium cutting precision to the next level.

Our industrial-grade CNC router tables are built with the rigidity and powerful spindles needed to handle the demands of metal machining. Ready to increase the speed and quality of your CNC cut aluminum fabrication?

Contact Cutting Edge Plasma today to discuss a CNC router solution that perfectly matches your metal cutting requirements.

Frequently Asked Questions (FAQs)

Q1. Can a standard CNC router really cut aluminium?

Yes, a rigid CNC router with a powerful spindle can effectively cut aluminium, but it requires significantly different tooling and settings compared to wood. You must use carbide bits, slow the depth of cut, and implement active cooling/lubrication.

Q2. What is the best aluminium alloy for CNC routing?

The most commonly recommended alloy for CNC cut aluminum with routers is Aluminium 6061-T6. It is relatively hard and easy to machine, offering a good balance of strength and chip-breaking characteristics, making CNC router cutting aluminium 6061 straightforward.

Q3. Why does aluminium stick to the cutter?

Aluminium has a low melting point. The friction and heat generated during the cut can cause the chips to soften and melt, welding or sticking to the cutter's edge. This is called Built-Up Edge (BUE) and is prevented by proper cooling and high chip loads.

Q4. Is it possible to rout half half-inch aluminum 1 pass?

It is strongly discouraged. Cutting half-inch aluminum 1 pass puts extreme stress on the tool and machine, likely leading to excessive heat, poor finish, and tool breakage. Always use multiple, shallow passes to maintain a manageable chip load and temperature.

Q5. What is chip load, and why is it important for aluminium?

Chip load (or 'feed per tooth') is the thickness of material removed by each cutting edge. For aluminium, the chip load must be kept high enough to ensure the tool cuts a clean chip rather than rubbing the surface, which drastically reduces heat and improves the surface finish.

Q6. How do I get a good finish when cutting aluminum with a router?

Achieving a good finish relies on minimal heat and minimal vibration. Key techniques include using a sharp, coated single/two-flute carbide end mill, ensuring the correct chip load (no rubbing), firmly clamping the material, and using a coolant mist or air blast.