Plasma is one of the hottest technologies in metal cutting, and it's not just about temperature. When gases like air, oxygen, or nitrogen are superheated to over 20,000°C, they turn into plasma, a state of matter that can slice through steel, aluminum, and other metals with precision and speed.

The global plasma cutting machine market is valued at $1.86 billion in 2025, with projections to reach $2.23 billion by 2030, driven by demand in automotive, heavy machinery, and industrial fabrication. Plasma cutting is clearly the future of metal fabrication.

However, achieving clean, precise cuts on thick or tough materials can be challenging, and excessive heat can impact cut quality if not managed properly. That’s where plasma cutters excel. These machines harness plasma to deliver fast, accurate cuts while minimizing waste and reducing consumable wear.

Whether cutting mild steel, stainless steel, or aluminum, plasma cutting is one of the most cost-effective and efficient methods for high-quality results. This guide will explain how plasma cutting works, what makes up a plasma cutting system, and how to optimize performance.

Key Takeaways

Plasma cutting uses a high-temperature, electrically ionized gas to melt and remove material, allowing for fast, precise cuts on metals like steel, aluminum, copper, and brass.

A plasma cutting system consists of a power supply, plasma torch, arc starter, consumables (electrode, nozzle, shield), and a gas supply (air, oxygen, nitrogen, argon).

Plasma cutting works on all electrically conductive metals, with steel, stainless steel, and aluminum being the easiest to cut. Copper and brass require careful selection of gas and amperage.

Key advantages include high-speed cutting, clean edges, low heat-affected zones (HAZ), versatility with different metals, and cost-effectiveness for production workflows.

Limitations include inability to cut non-conductive materials, edge beveling on thick metals, noise, fumes, and the need for regular maintenance due to consumable wear.

What Is Plasma Cutting?

Plasma cutting is a metal-cutting process that uses a high-temperature, electrically conductive stream of ionized gas, known as plasma, to melt and blow away material. Plasma forms when a gas (such as compressed air, nitrogen, or oxygen) is energized to the point that its atoms break apart into electrons and ions.

This creates a superheated, focused arc capable of reaching temperatures above 20,000°C, making it powerful enough to cut through steel, stainless steel, aluminum, brass, and other conductive metals with speed and precision.

This combination of extreme heat and force makes plasma cutting both fast and efficient, significantly quicker than mechanical cutting and, in many cases, even faster than oxy-fuel methods.

Common Applications of Plasma Cutting

Because of its versatility, plasma cutting is used across numerous industries, including:

Metal fabrication and welding shops: For cutting sheets, plates, brackets, frames, and components.

Automotive repair and restoration: For frame modification, rusted bolt removal, bodywork trimming, and custom fabrication.

CNC plasma cutting: For producing complex shapes, signage, artwork, brackets, gears, and industrial parts.

Industrial manufacturing: For high-volume cutting of metal components in construction, shipbuilding, machinery production, Heating, Ventilation, and Air Conditioning (HVAC), and heavy equipment.

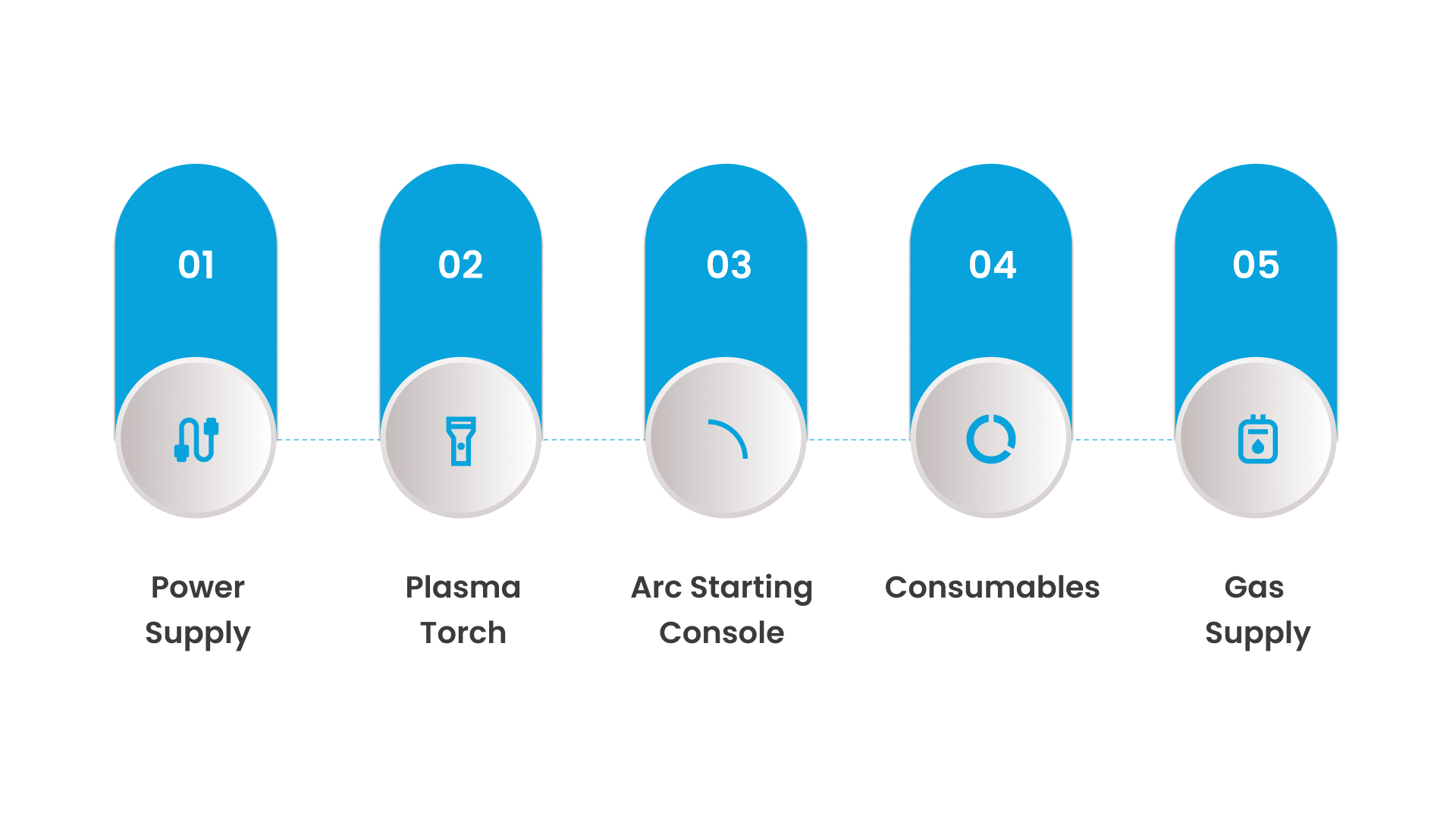

Components of a Plasma Cutting System

A plasma cutter is more than a torch. It's a coordinated system where every component plays a specific role in producing a stable, powerful cutting arc. Here are the important components of a plasma cutting system:

Power Supply

The power supply regulates the electrical energy delivered to the torch. It controls voltage, current (amperage), and cutting modes to ensure consistent arc performance. Higher amperages allow thicker materials to be cut.

Plasma Torch

The torch houses the electrode, nozzle, swirl ring, and shield. It directs the gas and electric arc through its consumables to form the plasma jet. Torch design heavily influences cut quality, cooling efficiency, and consumable life.

Arc Starting Console

Also known as the High-Frequency (HF) or pilot arc system, the arc starter initiates the plasma by generating a spark that ionizes the gas. Some systems use a high-frequency start, while others use a blowback-start mechanism for cleaner operation.

Consumables (Electrode, Nozzle, Shield)

Consumables shape and stabilize the plasma arc.

Electrode: Conducts the electrical current into the gas stream.

Nozzle: Constricts the arc to create a focused cutting jet.

Shield cap: Protects the nozzle and improves arc stability.

These wear down over time and must be replaced regularly to maintain cut quality.

Gas Supply (Air, Nitrogen, Oxygen, Argon Mixes)

The gas plays two roles: it becomes plasma, and it blows molten metal away.

Air: Common for general cutting.

Nitrogen: Good for stainless steel and aluminum.

Oxygen: Increases cutting speed on carbon steel.

Argon or argon-hydrogen mixes: Used for high-precision industrial applications.

Maintaining precise, efficient plasma cutting operations requires more than just skilled operators. Cutting Edge Plasma helps optimize performance by combining advanced machines with best-practice guidance and structured maintenance support.

Machines like the iPlasma XTREME 5100 CNC Plasma Table, iPlasma XTREME 4800 CNC Plasma Table, and iPlasma PRO 4800 CNC Plasma Table are engineered for consistent, high-quality cuts.

By using Cutting Edge Plasma’s solutions, you can benefit from predictable throughput, reduced unplanned downtime, and improved operational efficiency, giving fabrication and production teams the confidence to meet tight schedules and maintain high-quality standards.

Types of Plasma Cutting Systems

Plasma cutting technology comes in several forms, each tailored to specific applications, precision needs, and production volumes. Understanding the differences helps you choose the right system for your workflow.

Type of System | Key Features | Precision Level | Best For |

|---|---|---|---|

Conventional Plasma Systems | Uses single gas (air), standard consumables | Moderate | General fabrication, repair work, and small shops |

High-Definition (HD) Plasma Systems | Specialized gases, advanced torch & consumables | High | Industrial manufacturing, precision cutting |

CNC Plasma Cutting Tables | Computer-controlled cutting, automated motion | Very High | Manufacturing, HVAC, signage, metal art |

Handheld Plasma Cutters | Portable, manual operation | Variable (depends on operator skill) | On-site repair, automotive work, farm equipment, and small shops |

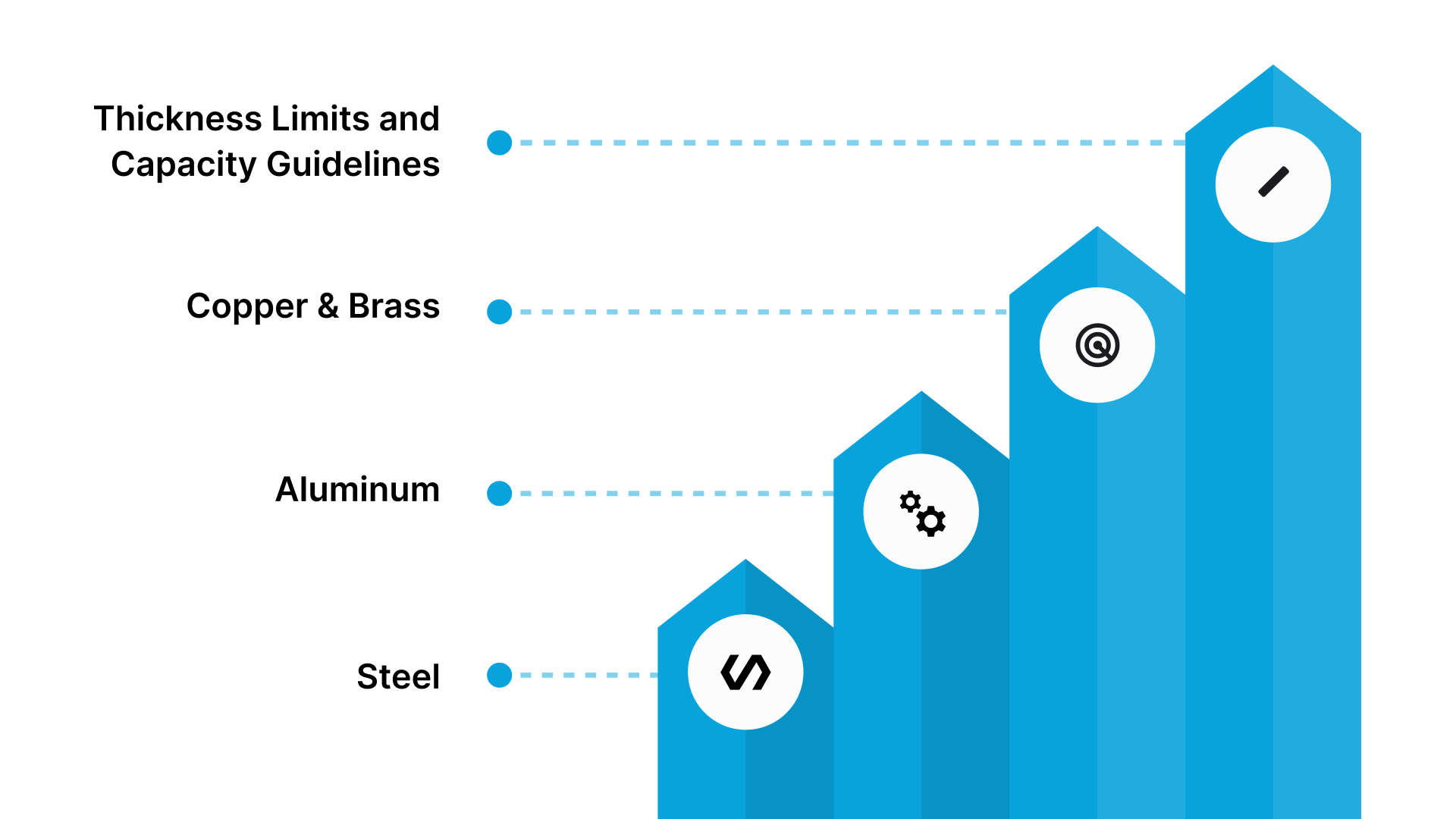

Materials Suitable for Plasma Cutting

Plasma cutting works on any electrically conductive metal, making it a versatile choice across fabrication, automotive, industrial, and repair applications. Its ability to deliver clean, fast cuts on both thin sheets and thick plate makes it essential in modern metalworking.

Steel (Mild and Stainless)

Steel is the most common material used with plasma cutting due to its excellent conductivity and predictable behavior under heat.

Mild steel cuts quickly with smooth edges and minimal slag.

Stainless steel also performs well, especially when using nitrogen or mixed gases to reduce oxidation.

Plasma’s high heat concentration ensures consistent results even on thicker steel sections.

Aluminum

Aluminum responds well to plasma because of its conductivity and relatively low melting point.

Produces clean, fast cuts with minimal warping.

Works best with nitrogen or specially mixed gases.

Since oxy-fuel cannot cut aluminum, plasma becomes the preferred choice for this material.

Copper and Brass

Copper and brass are more challenging because they conduct heat away from the cut zone quickly.

Modern high-definition systems can still cut these materials effectively.

Gas selection and proper amperage are crucial for maintaining cut quality.

These metals require more precision but are still well within the plasma’s capability.

Thickness Limits and Capacity Guidelines

Plasma cutters come in various power levels, and the material thickness capacity depends largely on amperage and system design. Here are general capacity ranges:

40–60 Amp Systems: Ideal for thin to medium materials; clean cuts up to 12–16 mm (1/2 inch).

80–100 Amp Systems: Suitable for thicker plate; clean cuts up to 25 mm (1 inch).

200+ Amp Industrial Systems: Designed for heavy plate; clean cuts up to 50–70 mm (2–2.75 inches).

Severance Limits: Many machines can sever up to 75 mm (3 inches), though at slower speeds and with rougher edges.

Benefits of Plasma Cutting

Plasma cutting offers several advantages that make it a preferred choice for fabricators, manufacturers, and repair professionals seeking fast, precise, and cost-efficient metal cutting.

High cutting speeds compared to oxy-fuel: Plasma cutting delivers significantly faster cutting speeds than oxy-fuel, allowing quicker production, reduced downtime, and improved throughput across fabrication workflows.

Clean edges and minimal finishing: The focused plasma jet creates smooth, precise edges with less slag, reducing grinding, cleanup time, and overall finishing labor after cutting.

Works on any conductive metal: Plasma easily cuts mild steel, stainless, aluminum, copper, and brass, offering unmatched versatility across industries needing reliable metal-cutting capabilities.

Lower Heat-Affected Zone (HAZ): The concentrated arc limits heat spread, minimizing warping, material distortion, and structural changes while preserving metal integrity near the cut area.

Cost-effectiveness and efficiency improvements: Plasma reduces labor, speeds production, lowers consumable use, and increases precision, delivering long-term operational savings and higher process efficiency overall.

Limitations of Plasma Cutting

While plasma cutting is highly versatile and efficient, it does come with certain limitations that users must consider when selecting the right cutting method.

Not suitable for non-conductive materials: Plasma cutting only works on electrically conductive metals, meaning materials like wood, plastic, glass, and ceramics cannot be processed using this method.

Edge beveling on thick materials: When cutting very thick plate, the plasma arc can widen or angle slightly, causing beveled edges that may require secondary finishing.

Noise, light, and fume considerations: Plasma cutting generates intense noise, bright UV light, and metal fumes, requiring proper ventilation, eye protection, and hearing safeguards for safe operation.

Consumable wear and maintenance needs: Nozzles, electrodes, and shields wear out over time, affecting cut quality. Regular inspection and replacement are necessary to maintain consistent performance.

Best Practices for Precision Plasma Cutting

Achieving clean, accurate, and consistent plasma cuts requires proper preparation, controlled technique, and strict attention to safety. Adopting the following best practices will help maximize performance and extend the life of your equipment.

Setup and Preparation

Effective plasma cutting begins long before the torch touches the metal. Proper setup ensures stable arc performance, smooth edges, and longer consumable life.

Choosing the right gas: Select the gas based on the material. compressed air for general cutting, oxygen for fast steel cuts, and nitrogen or argon mixes for stainless or aluminum.

Setting amperage correctly: Match the amperage to the material thickness. Too low causes incomplete cuts, while too high widens the kerf and wears consumables faster.

Checking consumables: Inspect the electrode, nozzle, and shield for wear or damage. Worn consumables cause poor arc focus, dross buildup, and inconsistent cut quality.

Ground clamp placement: Attach the ground clamp securely to clean metal close to the cutting zone. Poor grounding leads to arc instability and uneven cuts.

Torch height settings: Maintain proper torch-to-work distance using a height control system or manual adjustment. Correct height ensures stable arc formation and minimal bevel.

Cutting Techniques

Precise cutting depends on maintaining consistent motion, speed, and torch alignment throughout the process.

Correct cutting speed: Move too slowly, and you create excess dross; move too quickly, and the arc may fail to penetrate fully. Aim for a smooth, even spark trail.

Consistent torch angle: Hold the torch perpendicular to the workpiece for straight cuts. A slight angle may be used intentionally for beveling or removing dross.

Managing pierce delay: Allow the plasma jet to fully pierce the metal before beginning a cut. Starting too early results in blowback and damaged consumables.

Avoiding dross formation: Use correct height, amperage, and speed. Lower speeds typically cause top dross, while excessive speed creates bottom dross.

Keeping standoff height uniform: Uniform standoff ensures constant arc intensity and cleaner edges. CNC systems achieve this automatically; handheld users must be steady and precise.

Techniques for cutting curves and fine details: Slow down slightly during tight curves, maintain steady motion, and use shorter torch leads for better control. CNC tables excel at intricate patterns.

Safety Best Practices

Plasma cutting involves extreme heat, bright UV light, and airborne metal particles. Safety measures are essential to protect workers and the work environment.

Gloves, face shield, welding helmet, fire-resistant clothing: Use insulated gloves, a face shield or welding helmet with proper shade, and flame-resistant clothing to prevent burns from sparks and UV exposure.

Proper ventilation and fume extraction: Plasma cutting generates metal fumes that must be captured with ventilation systems, downdraft tables, or portable fume extractors.

Noise protection: Cutting operations can exceed safe noise limits; earplugs or earmuffs are necessary to prevent long-term hearing damage.

Fire safety considerations: Keep flammable materials away, have an extinguisher within reach, and maintain a clean workspace. Sparks can travel several meters and ignite debris.

How Cutting Edge Plasma Helps

If you’re evaluating ways to adopt plasma cutting, whether for small-scale fabrication, prototyping, or industrial-scale metalwork, Cutting Edge Plasma offers a turnkey solution that can simplify the process, reduce upfront investment, and deliver high-quality results.

Integrated CNC Plasma Tables with Smart Controls: Our CNC tables come pre-equipped with features like Torch-Height Control (THC), which automatically maintains consistent torch-to-metal distance, a critical factor for clean, precise cuts even on warped or uneven metal surfaces.

User-Friendly Software & Motion Control: Our machines run on modern control software compatible with current operating systems, enabling operators to easily program toolpaths, manage feed rates, and adjust lead-ins/lead-outs.

Waterbed Cutting Tables to Reduce Smoke and Dust: The standard inclusion of a waterbed under the cutting area helps suppress smoke and dust, and also helps cool the material, reducing warping and improving cut quality.

Support & Warranty: Cutting Edge Plasma offers lifetime technical support and a warranty period on machining and electronics, giving users a reliable support network, especially useful for shops new to CNC-plasma cutting.

Whether you have a small fabrication shop or a startup that needs quality plasma cutting without investing heavily in multiple machines or infrastructure, you can simply rely upon Cutting Edge Plasma.

Conclusion

Plasma cutting has earned its place as one of the most versatile and efficient metal-processing methods available today. From handheld units used in repair shops to advanced high-definition and CNC-driven systems powering industrial production lines, the technology offers speed, precision, and adaptability.

For workshops or businesses looking to adopt or upgrade plasma capabilities, solutions from providers like Cutting Edge Plasma make the transition smoother and more cost-effective. With reliable equipment, smart controls, and ongoing support, it becomes easier to unlock the full potential of plasma cutting and integrate it seamlessly into your workflow.

Ready to Upgrade Your Cutting Capabilities?

Cutting Edge Plasma offers high-performance CNC plasma tables, expert support, and reliable parts to help you achieve cleaner cuts, faster production, and long-term efficiency.

Contact us today and take your metal fabrication to the next level.

FAQs

1. What is plasma cutting good for?

Plasma cutting is ideal for quickly and precisely cutting electrically conductive metals such as steel, stainless steel, aluminum, copper, and brass, across various thicknesses, for fabrication, automotive, and industrial applications.

2. What gas is used for plasma cutting?

Plasma cutting uses compressed gases like air, nitrogen, oxygen, argon, or argon-hydrogen mixes. Gas choice depends on material type, desired cut quality, and system capabilities, optimizing speed and edge smoothness.

3. Is plasma cutting AC or DC?

Most plasma cutting systems use direct current (DC) to maintain a stable, focused arc. Some specialized applications may use AC, but DC remains the standard for precision cutting in fabrication.

4. Can you plasma cut without gas?

No, plasma cutting requires a flow of ionized gas to create the plasma arc. Without gas, the metal cannot ionize, and the cutting process will not function effectively.

5. Is a CNC a plasma cutter?

A CNC (Computer Numerical Control) is not a plasma cutter itself. It’s a motion control system that can operate a plasma cutter for automated, precise, and repeatable cuts.