Plasma tables play a crucial role in metal fabrication, delivering the accuracy needed to cut, shape, and finish metal components with consistency. They are especially valuable for applications that require clean edges, detailed profiles, and repeatable cuts, all of which support high-quality production output.

However, even a well-engineered system can fall short if operators do not fully grasp what a plasma table is and how it works. Issues such as misalignment, incorrect settings, or improper torch handling can lead to scrap, workflow interruptions, and delays that affect overall productivity.

To help you avoid these challenges, this guide explains what a plasma table is and how it operates, presenting clear practices that improve accuracy, reliability, and efficiency throughout your fabrication process.

Key Takeaways

Plasma tables deliver precise, repeatable cuts on metals like steel, stainless steel, and aluminum, ensuring consistent high-quality output.

CNC automation improves efficiency by reducing manual labor, limiting scrap, and speeding up production.

They are versatile across applications, including construction, shipbuilding, custom fabrication, and industrial operations.

Proper setup, CAD/CAM integration, torch control, and debris management are critical for reliable performance and safety.

Understanding what a plasma table is and how it works helps operations leaders maximize yield, reduce rework, and optimize ROI.

What is a Plasma Table? Insights for Accurate Metal Cutting

A plasma table cuts metal by directing a high-temperature plasma arc through conductive materials while the CNC system guides the torch along programmed paths.

This combination of plasma energy and automated motion allows you to create clean edges, detailed shapes, and consistent cuts across a wide range of applications. The quality of each cut depends on factors such as torch stability, cutting speed, and programmed design accuracy.

For fabrication teams, understanding what a plasma table is and how it functions is critical for maintaining precision, reducing waste, and supporting reliable production flow.

When used correctly, a plasma table helps you:

Produce smooth and uniform cuts on steel, stainless steel, aluminum, and other metals.

Save time compared to manual or semi-automated processes due to CNC-controlled movement.

Limit scrap and reduce the need for rework by ensuring consistent first-pass accuracy.

Support long-term performance through proper setup, handling, and routine maintenance.

To achieve faster cutting, higher accuracy, and less material waste, Cutting Edge Plasma provides products such as the iPlasma XTREME Series, designed for high-definition performance with models like the XTREME 5100 HD, XTREME 5100, XTREME 4800, and XTREME 4400.

For consistent everyday manufacturing, the iPlasma PRO Series offers dependable options including the PRO 4800 and PRO 4400.

Each machine is built to support accurate cutting, efficient workflow, and long-term reliability, helping manufacturers improve quality, speed, and overall production efficiency in metal fabrication

Gaining clarity on what a plasma table is and how it works equips your operation to run more efficiently and consistently from one project to the next.

How Plasma Tables Compare to Other Metal Cutting Tools?

Before selecting equipment, it helps to understand what a plasma table is and how its capabilities differ from other cutting methods used in fabrication. Each tool operates with unique strengths and limitations, and these differences directly influence scrap rates, throughput, and production efficiency.

The table below highlights how key metal cutting tools compare in terms of operation, cutting approach, and overall production impact.

Tool Type | Difference | Operational Impact |

Oxy-fuel | Manual process and slower cutting | Increased scrap and reduced throughput |

Laser cutter | High precision with limited thickness range | Best for thin sheets and higher cost per unit on thicker metals |

Plasma table | Automated, versatile, and repeatable | Handles complex profiles, ensures consistent quality, and lowers labor requirements |

With these distinctions clear, the next step is to look at the components that make a plasma table precise, reliable, and suitable for high-volume metal fabrication.

Core Components That Make a Plasma Table Precise and Reliable

Each cutting method brings its own strengths to the shop floor, and understanding these differences helps you decide where a plasma table truly fits in your workflow. Before you look at what a plasma table can offer, it helps to see how it stacks up against other common metal cutting tools.

The comparison below makes it easier to see how each tool operates and what that means for day-to-day production.

Component | Function | KPI Impact |

Frame & Gantry | Provides structural support and smooth motion | Reduces vibration, ensures cut accuracy, lowers scrap |

Plasma Torch | Directs plasma stream | Enhances first-pass yield and edge quality |

Electrode & Nozzle | Focuses plasma | Improves consistency, reduces downtime |

Motors (Stepper/Servo) | Moves the gantry and torch | Ensures precise cut paths and repeatability |

Control System & Software | Integrates CAD/CAM files | Reduces errors, enables complex cuts |

Cutting Surface (Waterbed/Downdraft/Open) | Supports material and manages debris | Maintains cut quality, protects operators |

Knowing the components, plasma tables come in different types, each with specific benefits and considerations.

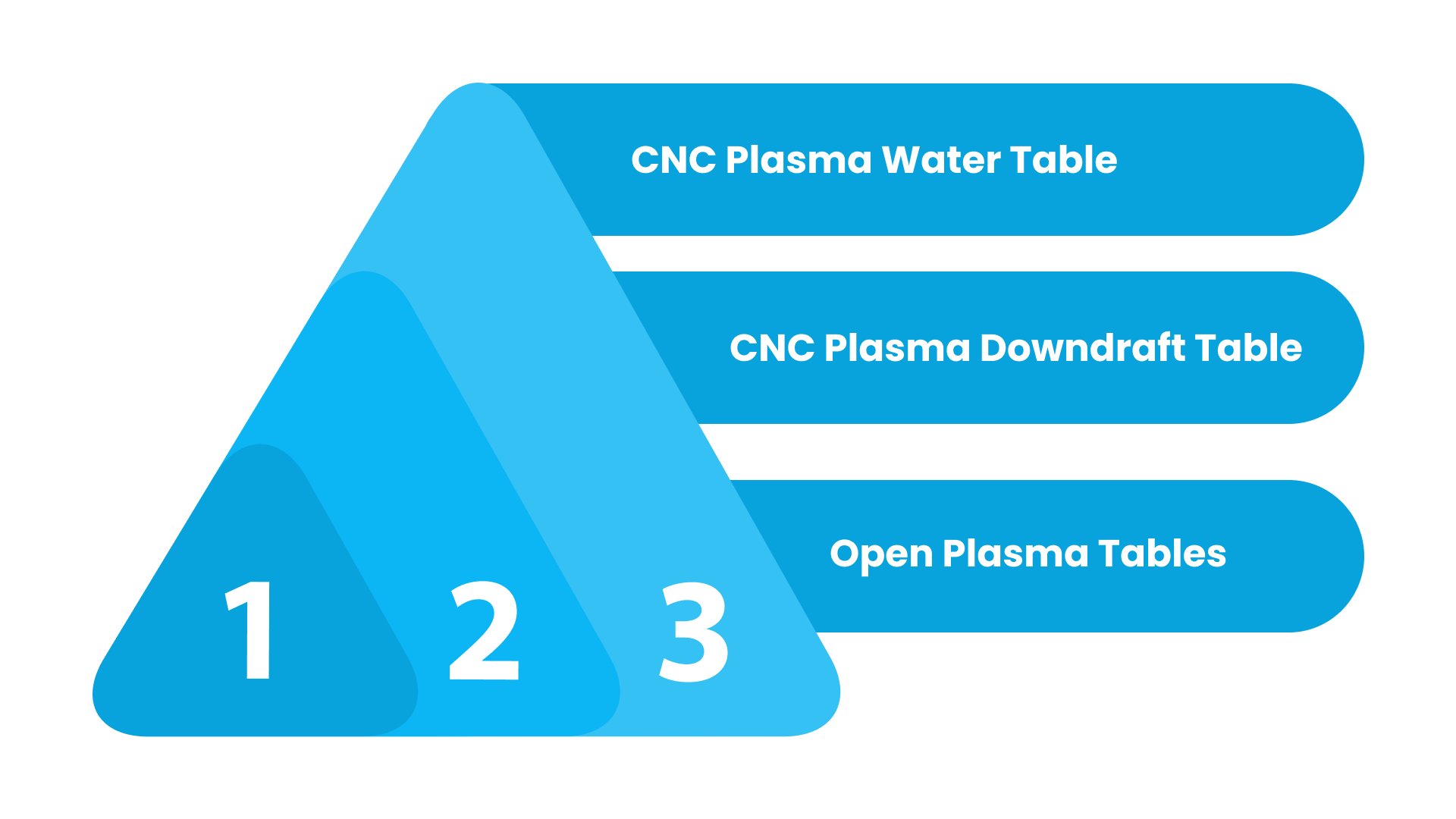

3 Types of Plasma Tables

Choosing the right plasma table depends on your production goals, available floor space, and how you plan to manage heat, dust, and material movement. Each setup offers unique strengths, and understanding these options helps you match the system to your workflow.

1. CNC Plasma Water Table

This type uses a water bed to cool the material during cutting. The cooling effect helps reduce warping and keeps dust and fumes under control. It is a strong choice when you need cleaner cuts and greater dimensional stability.

One thing to keep in mind is regular water maintenance, especially if you are running continuous or high-precision jobs.

2. CNC Plasma Downdraft Table

A downdraft system pulls smoke and debris down through the table to keep the cutting area clear. This design supports heavy-duty work and helps maintain a cleaner environment during long production runs.

You will need to monitor airflow and filtration to keep performance consistent, especially in high-volume operations.

3. Open Plasma Tables

Open tables provide more working room and easier access when loading or flipping large sheets. This flexibility is useful when handling oversized materials or irregular shapes.

However, since there is no built-in containment, dust, slag, and fumes require more attention. Good ventilation and cleanup routines are essential to keep the area safe and controlled.

Depending on the workspace and operational requirements, it’s equally important to see how they interact during the cutting process to achieve consistent results.

How a Plasma Table Operates Within Modern Fabrication?

A plasma table uses a combination of CNC automation and a high-temperature plasma arc to turn digital designs into accurate metal cuts. and reliable output. When every stage of the process is carefully arranged, the plasma table achieves precise edges, consistent quality, and efficient performance.

Here’s a step-by-step operational workflow:

1. CAD/CAM Integration

The process begins with preparing your design. A CAD file is imported into the CAM software, where cut paths, pierce points, and speed settings are defined.

Once configured, the file is sent to the plasma table’s control system. This step ensures the machine knows exactly what to cut and how to move.

2. Torch Positioning and Setup

Before cutting starts, the plasma torch is calibrated based on material type, thickness, and desired cut quality. Operators adjust torch height, gas flow, and amperage to match the job.

Proper setup here is essential because it directly influences edge quality and reduces the chances of warping.

3. Automated CNC Cutting

Once the program runs, the CNC gantry moves the torch along the defined path. The plasma arc melts the metal instantly, while pressurized gas blows the molten material away.

This combination of heat and gas produces precise cuts with minimal manual involvement. The automation ensures every part matches the digital design.

4. Debris and Heat Management

During cutting, smoke, dust, and slag are managed through either a water table or a downdraft system. Water absorbs heat and traps particles, while downdraft tables pull debris downward through built-in airflow channels.

Effective management keeps operators safe and maintains a cleaner work environment.

Operational Impact:

Reduces rework: Consistent torch height, stable motion control, and precise pathing help achieve accurate cuts the first time.

Improves throughput: Automation limits manual adjustments and speeds up batch production, especially for repetitive jobs.

Enhances safety and material protection: Controlled heat, managed debris, and predictable cutting conditions help protect both operators and workpieces.

Choosing the type is just the start but understanding how plasma tables translate into operational advantage is critical for making ROI-driven decisions.

3 Main Advantages of Using Plasma Tables

In modern metal fabrication, plasma tables have become essential for achieving precision, efficiency, and consistency. Understanding the advantages of these systems helps operations leaders see how they directly contribute to plant performance and overall productivity.

Plasma tables provide several operational benefits that make them a smart investment for any fabrication setup:

1. Versatility: Plasma tables can cut a wide range of metals and thicknesses without changing setups. This flexibility makes them suitable for varied projects and reduces the need for multiple cutting systems.

2. Precision and Speed: Equipped with CNC control, plasma tables deliver highly repeatable cuts. This ensures minimal scrap, faster production, and reliable outcomes on every job.

3. Cost Efficiency: Automation reduces labor requirements and helps control material waste. By simplifying production processes, plasma tables improve cost-effectiveness across operations.

Key Performance Benefits:

Higher first-pass yield: Accurate cuts reduce the need for rework, saving time and resources.

Reduced downtime: Quick setup and minimal manual intervention keep production running smoothly.

Stable lead times: CAD/CAM integration allows for predictable timelines for both custom orders and batch production.

Beyond internal efficiency, plasma tables are highly adaptable across industries, from automotive and heavy fabrication to industrial manufacturing. Their versatility and reliability make them a valuable asset in any metalworking environment.

How Different Industries Benefit from Plasma Tables?

Plasma tables are widely used in industries where precision, speed, and repeatable quality are essential. Their versatility allows them to handle a variety of projects, from large-scale structural work to custom, one-off pieces. To better understand their impact, consider how they are applied across different sectors:

1. Construction & Structural Fabrication: In construction, plasma tables enable rapid cutting of steel beams and plates, helping projects stay on schedule while minimizing material waste.

2. Shipbuilding: For shipbuilding, they handle complex, curved cuts on large components, ensuring precision and consistency even on intricate designs.

3. Custom Fabrication: When it comes to custom or small-batch projects, plasma tables deliver predictable quality, making them ideal for specialty parts, prototypes, and one-off metalwork.

Operational Insight

Across all these applications, plasma tables scale effectively from small workshops to large industrial operations, maintaining consistent output, minimizing downtime, and optimizing production costs, thanks to high-quality motors and precise CNC control systems.

How To Strengthen Your Metal Fabrication with Cutting Edge Plasma Tables?

Cutting Edge Plasma systems are designed to streamline your workflow while delivering dependable results. They offer accuracy, prioritize operator safety, and maintain consistent performance across every project.

Here’s a look at how our features make operations easier and give you a clear understanding of what a plasma table is and how it functions:

1. Precision CNC Motion Control

The CNC motion system directs the plasma torch along pre-programmed paths with high accuracy. This allows for clean cuts, uniform edges, and repeatable outcomes, even on intricate designs or large metal sheets.

2. Torch Height Control (THC)

The THC feature maintains the proper distance between the torch and material at all times. This prevents overcuts or undercuts, protects the torch, and guarantees consistent results across metals of different thicknesses.

3. Integrated CAD/CAM Software

Seamlessly compatible with current design programs, this software lets you upload files, fine-tune cut paths, pierce points, and speed settings. All instructions are sent directly to the plasma controller, minimizing errors and keeping operations efficient.

4. Debris and Fume Management

Water tables and downdraft systems effectively manage heat, smoke, and slag. This keeps the workspace safe and clean while ensuring the material remains protected and cuts are precise.

5. Lifetime Tech Support and Warranty

Cutting Edge Plasma offers ongoing support to help you use your plasma table safely and efficiently. A one-year warranty covers electronics and workmanship, giving you confidence in daily operations.

With these features, you can fully grasp what a plasma table is, maintain safe operation, reduce mistakes, and achieve high-quality, repeatable results. CNC control, torch height management, smart software, and a clean cutting environment make it easier to work accurately and efficiently.

Conclusion

Plasma tables from Cutting Edge Plasma are crafted to make metal cutting more accurate, consistent, and efficient.

With reliable motion control, stable construction, and clean arc performance, these systems help you reduce scrap, avoid unplanned downtime, and maintain dependable quality across production.

By applying the core principles of what a plasma table is and how it works, your team can operate with greater safety, precision, and confidence. From routine cuts to detailed patterns, the right setup ensures smooth and repeatable results every time.

Contact Cutting Edge Plasma today to explore full range of plasma cutting systems and get expert guidance to support clean, professional outcomes on every project.

FAQs

1. How does a plasma table help in metal fabrication?

A plasma table uses a high-temperature plasma arc to cut through conductive metals with precision. The machine moves along programmed paths, allowing clean and consistent cuts. Understanding what a plasma table is and how it works helps you handle projects with accuracy and efficiency.

2. Which materials can a plasma table cut?

Plasma tables can cut steel, stainless steel, aluminum, and other conductive metals. Knowing what a plasma table is and how it works makes it easier to choose the right material thickness and settings for your projects.

3. What are the main components that explain what a plasma table is and how it works?

A plasma table includes a power supply, torch, motion system, and control software. Each part plays a role in explaining what a plasma table is and how it works by regulating the arc, guiding movements, and ensuring controlled cutting.

4. How does a CNC controller help a plasma table work accurately?

The CNC controller directs the torch using programmed designs. This automation supports consistent motion, detailed shapes, and repeatable results, helping you understand what a plasma table is and how it works during real-time cutting.

5. What safety steps should I follow while learning what a plasma table is and how it works?

Wear protective gear, keep the workspace clear, and ensure proper grounding. These practices help you operate safely while learning what a plasma table is and how it works, reducing risks and supporting smoother workflows.