In a world where precision, speed, and efficiency define success in metal fabrication, a Computer Numerical Control (CNC) plasma table can make the difference between a project that drags on and one that cuts cleanly.

Whether you’re a hobbyist building custom metal art, a small‑scale workshop tackling bespoke jobs, or an industrial outfit churning out structural components, the plasma table you choose will shape the quality, speed, and cost‑efficiency of your work.

Now more than ever, plasma cutting is rising in importance. The global market for CNC plasma cutting machines is projected to hit roughly $707.5 million in 2025, with a steady growth rate (CAGR ~ 5.1%) expected through the next decade.

That means, whether you’re upgrading your garage setup or investing in a full‑blown shop, picking the right plasma table isn’t a small decision. The difference between a table that under‑delivers and one that becomes the backbone of your fabrication work can be enormous.

In this guide, you’ll learn exactly what to look for, from table size and material compatibility to control systems, build quality, software, and long‑term costs, so you can choose a CNC plasma table that matches your projects, your growth ambitions, and your budget.

Key Takeaways:

A CNC plasma table automates metal cutting, giving you cleaner, faster, and more repeatable results than manual plasma cutting.

Material compatibility and thickness capacity determine what metals you can cut and how clean your results will be.

Sturdy frames and quality components reduce vibration and help the machine stay accurate over years of use.

Safety features like fume control, grounding, and emergency stops are essential for safe operation.

Cutting Edge Plasma stands out with user-friendly machines, built-in torch height control, waterbeds, and lifetime tech support.

What is a CNC Plasma Table?

A CNC plasma table is a computer-controlled system designed to cut metal with precision using a plasma torch. Unlike traditional manual plasma cutting, which relies entirely on human skill and guidance, CNC tables automate the cutting process.

This automation allows for consistent, repeatable cuts, even for complex shapes and intricate designs.

Key Differences Between Manual and CNC Plasma Cutting:

Feature | Manual Plasma Cutting | CNC Plasma Cutting |

|---|---|---|

Precision | Operator-dependent; less consistent | High accuracy and repeatability |

Complexity | Simple shapes; freehand cutting | Complex patterns and designs are easily achieved |

Speed | Slower for large projects | Faster, especially for repetitive tasks |

Waste | More material waste | Optimized cuts reduce scrap |

Learning Curve | Easier to start, skill improves over time | Requires software and machine setup knowledge |

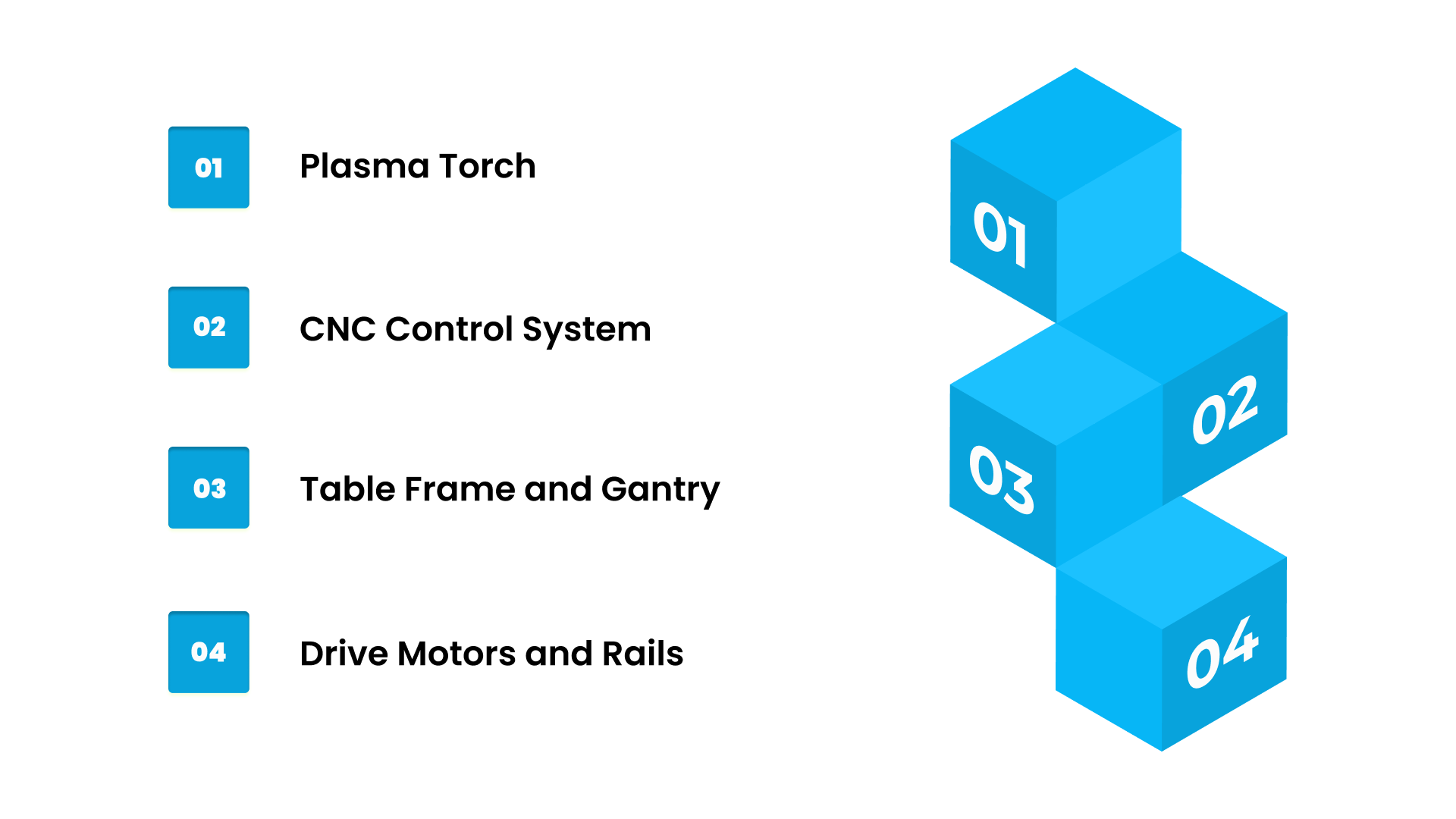

Key Components of a CNC Plasma Table

Understanding a CNC plasma table means knowing the essential components that make it work:

Plasma Torch: The core cutting tool that generates a high-temperature plasma arc to melt and slice through metal.

CNC Control System: The “brain” of the machine; it interprets design files (like CAD or DXF) and guides the torch with precision.

Table Frame and Gantry: Provides structural support, ensuring stability and minimizing vibrations for accurate cuts.

Drive Motors and Rails: Enable smooth, controlled movement along the X, Y, and sometimes Z axes, ensuring the torch follows the programmed path flawlessly.

How CNC Plasma Cutting Works?

The CNC plasma cutting process combines software, hardware, and plasma physics to achieve precise results:

Design Creation: A CAD drawing or DXF file is prepared for the part to be cut.

G-Code Generation: The design is converted into G-code, which instructs the machine on the torch’s movements.

Machine Setup: The material is placed on the table, and the plasma torch height and parameters are set based on the material type and thickness.

Cutting Process: The CNC system moves the torch along programmed paths. The plasma arc melts the metal, and compressed gas blows away the molten material.

Finishing: Once the cut is complete, parts may require minimal cleanup, depending on the material and precision.

The result is a highly efficient, repeatable process that produces accurate cuts faster than manual methods, with minimal waste and improved overall workflow.

Factors to Consider When Choosing a CNC Plasma Table

Selecting the right CNC plasma table involves more than just picking the first model you find. To ensure you get the best performance, longevity, and value, consider the following factors:

Cutting Area & Material Size

The size of your plasma table directly impacts the types of projects you can handle.

Standard Sizes vs. Custom Sizes: Standard tables cover most small-to-medium projects, while custom tables may be necessary for larger or irregular materials.

Matching Table Size to Material: Choose a table slightly larger than your typical material dimensions to allow for clamps, nesting, and optimal cutting paths.

Material Type & Thickness

Not all plasma tables cut every metal equally.

Compatible Metals: Steel, aluminum, stainless steel, and other conductive metals are commonly used.

Thickness Capacity: Verify both the maximum and minimum thickness the machine can handle to match your projects. Using a table outside its recommended range can reduce cut quality and shorten consumable life.

Cutting Precision & Tolerances

Accuracy is critical, especially for industrial parts or intricate designs.

High-precision tables can consistently cut within tight tolerances, reducing post-processing and material waste.

Consider the level of precision needed for your application before investing in higher-end models.

CNC System & Software

The control system determines how efficiently and accurately your table operates.

User-Friendly vs Advanced Software: Beginners may prefer intuitive interfaces, while advanced users might need features like nesting, parametric design, or automated toolpaths.

File Compatibility: Ensure the software supports standard design files (DXF, CAD) for seamless integration with your workflow.

Cutting Speed & Efficiency

Faster cutting can save time, but it shouldn’t come at the cost of quality.

Consider the trade-off between speed and precision.

Evaluate how cutting speed affects material consumption, electricity usage, and consumable lifespan.

Build Quality & Frame Construction

A solid frame ensures stability and long-term reliability.

Look for steel frames with quality welds, rigidity, and minimal vibration.

A strong structure contributes to more precise cuts and longer machine life.

Torches & Consumables

The plasma torch is the heart of your table, and consumables are a recurring cost.

Torch Types: Standard plasma torches work for most cuts, while high-definition torches offer cleaner, precise cuts for intricate projects.

Consumables: Check availability and costs of nozzles, electrodes, and other consumables to avoid surprises later.

Safety Features

Safety should never be overlooked in any metalworking environment. Key features include:

Fume extraction

Emergency stop buttons

Proper grounding

Shielding

Clear operational guidelines

Support & Warranty

Reliable manufacturer support can save you from costly downtime.

Look for warranties, readily available spare parts, and responsive technical support.

Check user reviews and forums to gauge real-world support experiences.

Budget Considerations

Budget is always a factor, but it should be balanced with functionality and long-term costs.

Consider upfront cost vs. features and capabilities.

Factor in operational costs: electricity, consumables, maintenance, and potential upgrades.

Choosing the right CNC plasma table is easier when you have a trusted partner. Cutting Edge Plasma helps buyers evaluate table size, material needs, precision expectations, and long-term costs with clear, practical guidance, no technical background required.

Tables like the iPlasma XTREME 5100 CNC Plasma Table - High Definition, iPlasma XTREME 4800 CNC Plasma Table, and iPlasma PRO 4400 CNC Plasma Table are engineered for dependable performance and simpler ownership.

With our experience and support, you get machines that offer steady performance, fewer interruptions, and easier day-to-day operation, helping you invest confidently and keep your projects running smoothly. Contact us today.

Types of CNC Plasma Tables

CNC plasma tables come in a variety of designs, each tailored to different project sizes, material types, and production requirements. Choosing the right type ensures efficiency, precision, and long-term reliability for your specific needs.

1. Hobbyist / Small Shop Tables

These compact, light-duty tables are designed for hobbyists, small workshops, and DIY fabricators. They typically feature smaller cutting areas, simpler drive systems, and basic CNC controls.

Ideal for: Custom metal art, small parts, home fabrication, prototyping.

2. Industrial / Production Tables

Built for high-volume, heavy-duty cutting, these tables are common in fabrication shops and industrial environments. They feature robust frames, powerful torches, and advanced drive systems for precision and speed.

Ideal for: Mass production, structural components, heavy fabrication.

3. High-Definition Plasma Tables

High-definition plasma tables use advanced torch technology and fine arc control to deliver cleaner, more precise cuts. They reduce dross and the need for post-processing, making them ideal for detailed or aesthetic projects.

Ideal for: Automotive parts, architectural metalwork, intricate designs.

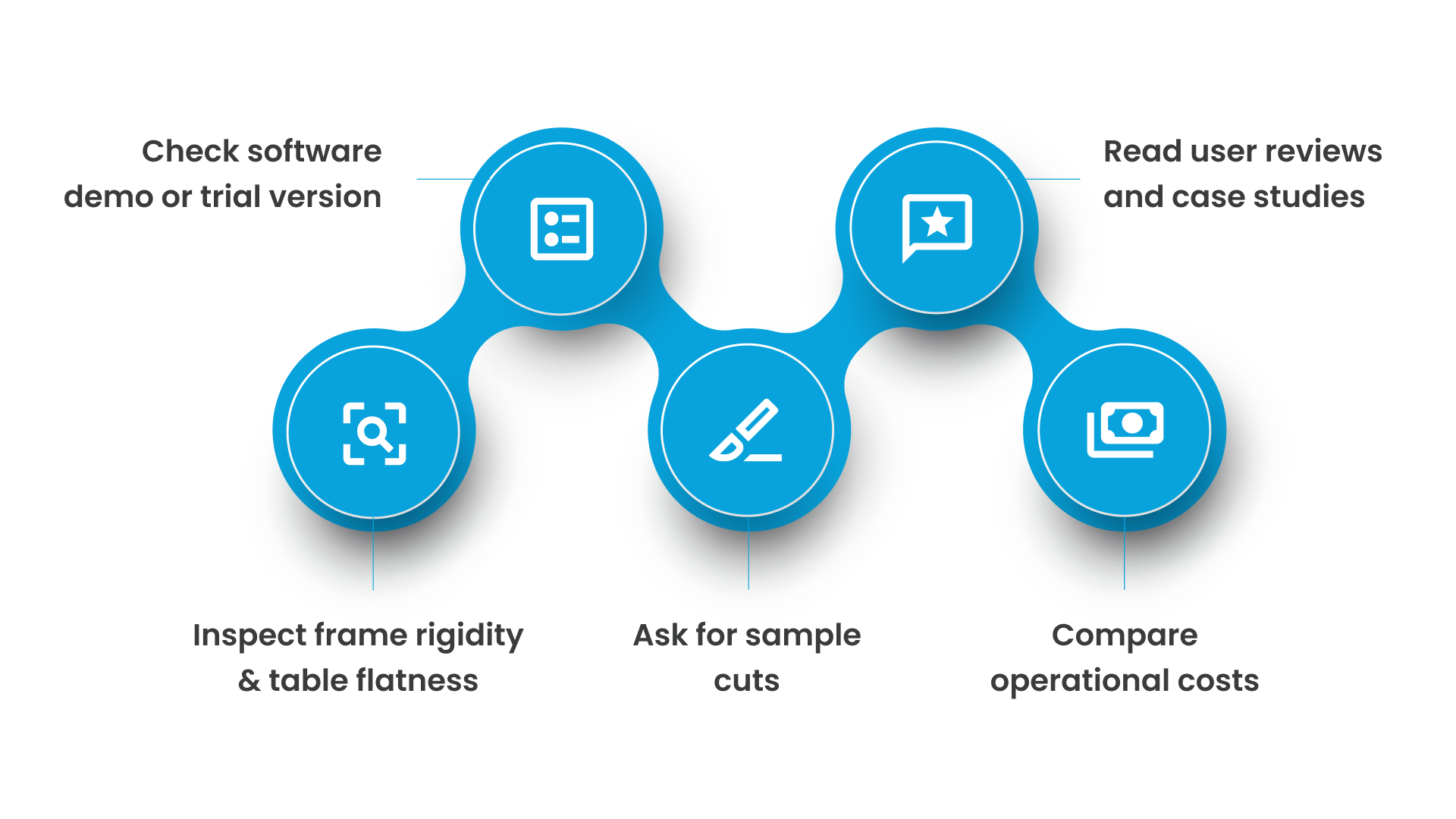

Tips for Evaluating CNC Plasma Tables

Choosing the right CNC plasma table requires more than comparing specifications on paper. The following evaluation tips will help you understand real-world performance, reliability, and long-term value before investing:

Inspect frame rigidity and table flatness: A rigid steel frame and perfectly flat table ensure stable movement, accurate cuts, less vibration, and consistent results across all materials.

Check software demo or trial version: Testing software firsthand reveals usability, file compatibility, nesting tools, workflow simplicity, and whether features match your production needs.

Ask for sample cuts: Reviewing real sample cuts exposes machine accuracy, edge quality, dross levels, kerf consistency, and true performance under actual cutting conditions.

Compare operational costs: Evaluate ongoing expenses, including consumables, electricity, maintenance, filters, and torch parts, to understand total ownership cost beyond the initial price.

Read user reviews and case studies: User feedback and case studies reveal long-term reliability, true performance, support quality, and whether the machine meets similar users’ expectations.

Common Mistakes to Avoid

Buying a CNC plasma table is a long-term investment, and avoiding these common pitfalls will save you money, frustration, and downtime.

Choosing Based on Price Alone: A low upfront cost can hide poor build quality, weak components, limited features, and higher long-term expenses due to frequent repairs or consumable use.

Ignoring Maintenance and Consumable Costs: Plasma cutting requires regular torch parts, filters, and upkeep. Overlooking these recurring costs can quickly exceed the initial savings of a cheaper machine.

Overlooking Support and Warranty Coverage: Strong customer support and a solid warranty are essential. Weak manufacturer assistance can lead to long downtime, costly repairs, and workflow interruptions.

Buying a Table Too Small for Future Projects: Choosing a small table restricts growth. As project sizes increase, you may need costly upgrades or a new machine altogether.

Why Cutting Edge Plasma Stands Out?

When you decide to invest in a CNC plasma or router table, the provider and after-sales support matter as much as the machine itself. That’s where Cutting Edge Plasma brings real value for buyers like you, whether you’re a hobbyist, a small workshop owner, or a growing fabrication business.

Integrated THC (Torch Height Control): Ensures that the torch stays at the correct height above the material for consistent cuts, which helps reduce scrap, improve cut quality, and prolong consumable life.

THC Anti-Dive: Ensures safe, precise torch behavior around corners or complex cuts.

Waterbed below cutting area: Helps in reducing dust, smoke, and heat distortion while cutting, making the working environment cleaner and improving cut stability.

By choosing a machine from Cutting Edge Plasma, you get more than hardware. Contact us today to know more.

Conclusion

Choosing the best CNC plasma table comes down to understanding your workflow, material requirements, precision expectations, and long-term production goals. By evaluating factors, you can confidently select a machine that delivers consistent results and real value over time.

Avoiding common pitfalls, like choosing solely on price or overlooking maintenance, will ensure your investment remains productive and reliable for years to come.

Ready to Choose the Right CNC Plasma Table?

If you want a machine that’s easy to use, reliable, and built for long-term performance, Cutting Edge Plasma can help you make the right choice.

With lifetime technical support, user-friendly software, and solid build quality, Cutting Edge Plasma gives you the confidence to invest in a machine that will grow with your projects and keep your workflow running efficiently.

Contact us today to explore our full range and find the table that fits your needs.

FAQs

1. What is the lifespan of a CNC plasma table?

A well-built CNC plasma table typically lasts 8–12 years with proper maintenance. High-quality components, regular cleaning, correct consumable use, and stable power conditions significantly extend long-term performance and reliability.

2. Can I cut aluminum with a standard plasma table?

Yes, plasma tables can cut aluminum effectively. Using proper amperage, clean dry air, correct consumables, and managing heat input ensures cleaner edges and minimizes warping or excessive dross formation on aluminum.

3. How often do consumables need replacement?

Consumable life depends on amperage, material thickness, air quality, and operator technique. On average, nozzles and electrodes last a few hundred cuts before performance drops and parts require replacement.

4. Is a water table necessary for precision cuts?

A water table isn’t mandatory, but it helps significantly. It reduces heat distortion, captures fumes, minimizes dross, and improves cut consistency, especially beneficial for thin metals or detailed, high-precision work.

5. Is a CNC plasma table worth it?

Yes, it’s worth it for most metal fabrication needs. CNC plasma tables offer fast cutting, good accuracy, lower operating costs, and versatility, making them ideal for shops needing repeatable, efficient production.

6. How accurate is CNC plasma cutting?

CNC plasma cutting typically achieves ±0.25–1 mm accuracy depending on machine quality, torch height control, and material thickness. High-definition systems deliver tighter tolerances, though still less precise than laser or waterjet cutting.