A CNC plasma table can shape how efficiently your shop operates, how clean your cuts look, and how much work you can handle in a day. For small fabrication units, metal art shops, automotive workshops, and custom manufacturing teams, the right machine supports steady output and consistent results without straining your budget.

With several options in the market, finding a reliable machine that offers industrial strength without demanding a massive upfront investment becomes essential.

This guide compares the best CNC plasma table for small businesses, their features, pricing, ideal use cases, and what makes each table stand out.

Key Takeaways

A CNC plasma table influences how efficiently small shops manage daily workloads by supporting cleaner cuts, steady accuracy, and smoother production flow.

Understanding how table size, frame strength, motors, and software affect output helps small businesses match a machine to real operational demands.

Consistent features like torch height control, rigid motion systems, and waterbeds reduce scrap, protect consumables, and keep production timelines predictable.

Comparing models based on workload, workspace, and long-term plans makes it easier to align the machine with both current and future shop requirements.

Systems built for reliability and low maintenance, such as Cutting Edge Plasma tables, support stable performance and reduce the risk of unnecessary downtime.

Why Small Businesses Should Invest in a CNC Plasma Table?

In a small manufacturing operation, every piece of equipment affects workflow, efficiency, and costs. A CNC plasma table is more than just a cutting tool, it shapes how quickly jobs are completed, how consistently parts are made, and how smoothly the shop runs day-to-day.

Here’s how it makes a real impact:

Faster project completion: Work moves seamlessly from design to finished parts, so a batch of custom panels or metal signage can be completed on schedule, keeping clients satisfied.

Reliable and precise results: Consistent cutting reduces material waste and the need for rework, making it easier to produce uniform parts for assemblies or product lines without interruptions.

Lower operational costs: Automated processes allow the team to focus on high-value tasks while cutting down on extra labor or outside services for cutting large sheets or intricate components.

Ability to take on bigger projects: The equipment handles more complex or larger jobs, making it possible to expand services to full-scale metal fabrication or multi-part assemblies.

Stable daily operations: Smooth, dependable performance keeps production flowing steadily, so schedules for multiple jobs or overlapping orders stay on track.

A well-chosen CNC plasma table helps maintain quality, reduces scrap, supports smoother workflows, and allows the business to grow while keeping costs predictable.

Being prepared for higher volumes reduces risk and keeps operations smooth. Models like the PRO Series and XTREME Series from Cutting Edge Plasma are ideal if long-term scalability is a priority.

With the role of CNC plasma tables clear, the next step is understanding the standout machines currently available.

10 Best CNC Plasma Tables for Small Businesses in 2025-26

Picking a CNC plasma table is easier when you compare what each model delivers in real shop conditions. Instead of sorting through long specifications sheets, it helps to focus on what each table is designed to handle, whether that’s tighter tolerances, larger sheet sizes, or steady day-to-day production.

The list below gives you a quick snapshot of the top models and router tables, so you can match the right machine to your workload, space, and future plans.

Model | Price | Best For |

$13,995 | Small shops that need an affordable, reliable starter CNC table. | |

$14,995 | Growing workshops that need steady output and more workspace. | |

$16,995 | Small businesses need higher accuracy and consistent production. | |

$17,495 | Mid-size shops are scaling production while maintaining accuracy. | |

$17,995 | High-volume fabrication requiring stronger speed and durability. | |

$27,000 | Shops needing premium accuracy and optional HD cutting quality. | |

Bosch RA1181 Benchtop Router Table | Varies | Woodworkers need a dependable all-purpose benchtop router table. |

Kreg PRS1045 Precision Router Table System | Varies | Professionals need a stable, freestanding router setup. |

Rockler Convertible Benchtop Router Table | Varies | Woodworkers who need portability without losing performance. |

Ryobi Intermediate Router Table | Varies | Hobbyists need a versatile and budget-friendly router table. |

Below, you’ll find the most dependable options known for their fully welded frames, side-load capability, high-rigidity rails, and maintenance-free operation.

1. iPlasma PRO 4400 CNC Plasma Table

Price: $13,995

Best for: New fabrication shops, metal signage businesses, and entry-level production

Features and Build Quality:

Ideal for small shops, the iPlasma PRO 4400 CNC Plasma table offers reliable, budget-friendly cutting without compromising durability. Its fully welded steel frame ensures stability, SG-25 guide rails on the Y-axis and a V-rail on the X-axis deliver smooth motion, and the 4" water bed keeps the workspace cleaner by reducing smoke and debris.

Compatibility with Plasma Cutters: It works with all standard plasma cutters, allowing easy integration with your current setup.

Included Accessories: A 24" computer display, Proma controller, proximity sensors, and the water table come standard with this model.

Special Features: The Z-axis offers 6" of travel, the Y-axis has dual drives, and the torch mount includes collision detection to prevent damage and avoid sudden downtime.

Ideal Use Case: This table is ideal for small workshops that need a reliable machine without stretching their budget.

2. iPlasma PRO 4800 CNC Plasma Table

Price: $14,995

Best for: Growing workshops, custom metalwork, and medium-scale production

Features and Build Quality

Designed for small to medium-scale shops, the iPlasma PRO 4800 CNC Plasma table combines reliability and efficiency for everyday cutting. The fully welded steel frame provides solid stability, while 25 mm speed guide rails on the Y-axis and a V-rail on the X-axis ensure smooth, accurate motion. A 4" water bed helps maintain a cleaner workspace by reducing smoke and debris.

Compatibility with Plasma Cutters: It supports standard plasma cutters and can be matched with a supplier-provided setup for more specialized needs.

Included Accessories: The package includes a 24" display, Proma controller, proximity sensors, and a water table for smoother operation.

Special Features: It provides 6" Z-axis travel for heavier materials, reinforced XY axis motion for long-term accuracy, and collision detection to reduce wear and protect the machine during operator errors.

Ideal Use Case: This model works well for workshops increasing their capacity while keeping production consistent.

3. iPlasma XTREME 4400 CNC Plasma Table

Price: $16,995

Best for: Small businesses and commercial shops needing consistent, accurate cuts for repeat production

Features and Build Quality

The iPlasma XTREME 4400 CNC Plasma table combines durability and accuracy in a compact design. Its fully welded, powder-coated frame ensures rigidity, the Y-axis uses a 35 mm speed guide rail, and the X-axis features a 30 mm dual rigid rail for smooth, consistent motion. A 4" water bed with slats helps control smoke and debris, keeping the workspace cleaner and easier to maintain.”

Compatibility with Plasma Cutters: It is compatible with a wide range of plasma cutters, making it flexible for various cutting applications.

Included Accessories: The table comes with a 24" computer display, Proma controller, and proximity sensors.

Special Features: It provides 8" Z-axis travel for improved flexibility across various material heights, NEMA 34 stepper motors on the XY axes for stable travel, and a collision-detection torch mount that reduces scrap by preventing misalignment during sudden bumps.

Ideal Use Case: This machine is suitable for workshops that need consistent high-quality output with minimal maintenance.

4. iPlasma XTREME 4800 CNC Plasma Table

Price: $17,495

Best for: Commercial fabrication, mid-size production, and larger workshops

Features and Build Quality

Built for busy workshops, the iPlasma XTREME 4800 CNC Plasma table delivers reliable and precise cutting. Its fully welded steel frame ensures stability, the Y-axis features a 35 mm speed guide rail while the X-axis uses dual rigid rails for smooth motion, and the 4" water bed keeps smoke and debris under control, maintaining a cleaner work area.

Compatibility with Plasma Cutters: The table works with most standard plasma cutters and allows easy integration for customized setups.

Included Accessories: A 24" display with computer, Proma controller, proximity sensors, and water table are included.

Special Features: It includes 8" Z-axis travel to handle taller fixtures and varied material thickness, Nema 34 stepper motors on XY for steadier motion during demanding cuts, and a collision-aware torch mount that keeps your cut path consistent even when the sheet isn’t perfectly flat.

Ideal Use Case: This table supports shops growing production while ensuring consistent, accurate cuts and reliable performance.

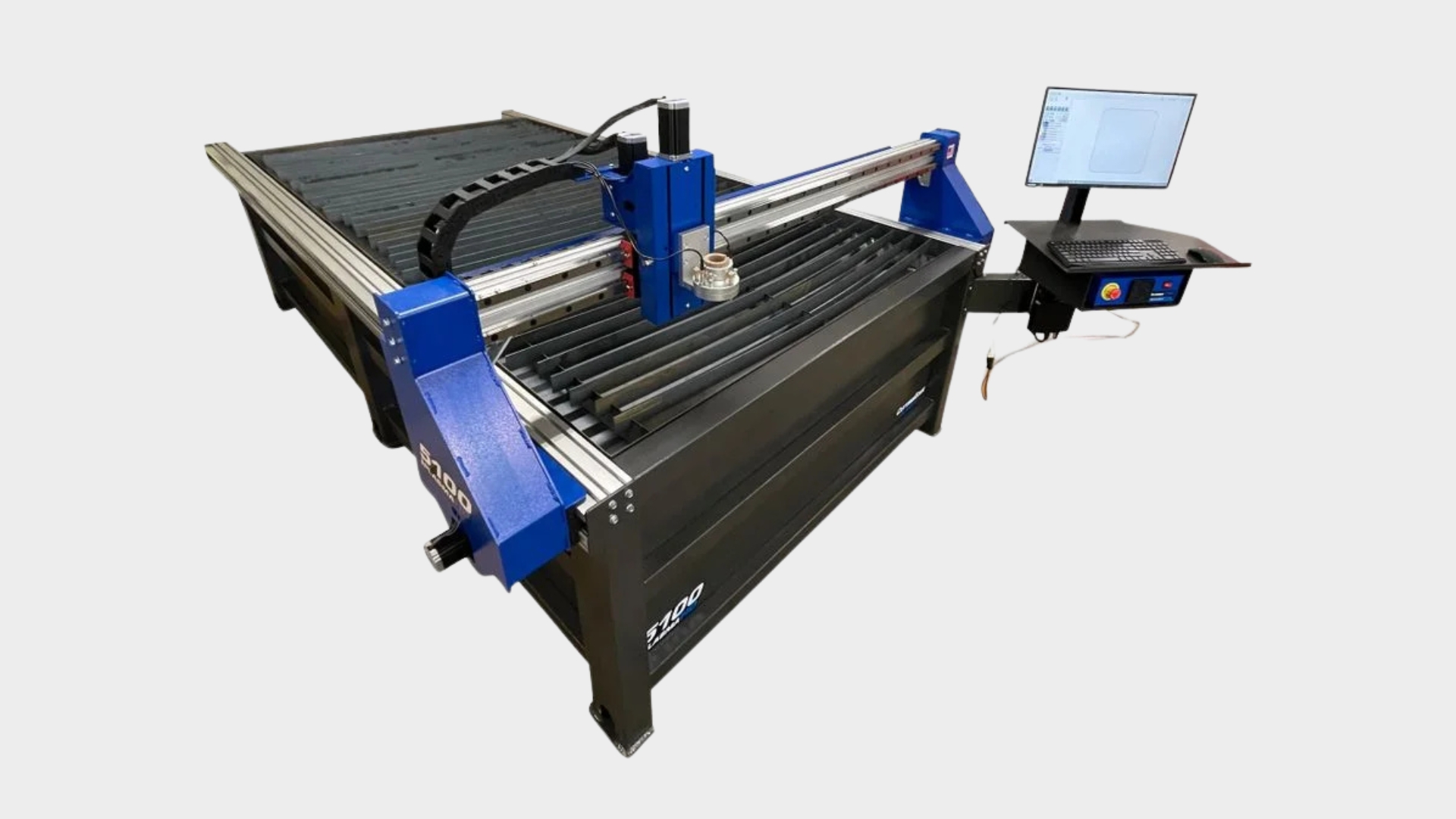

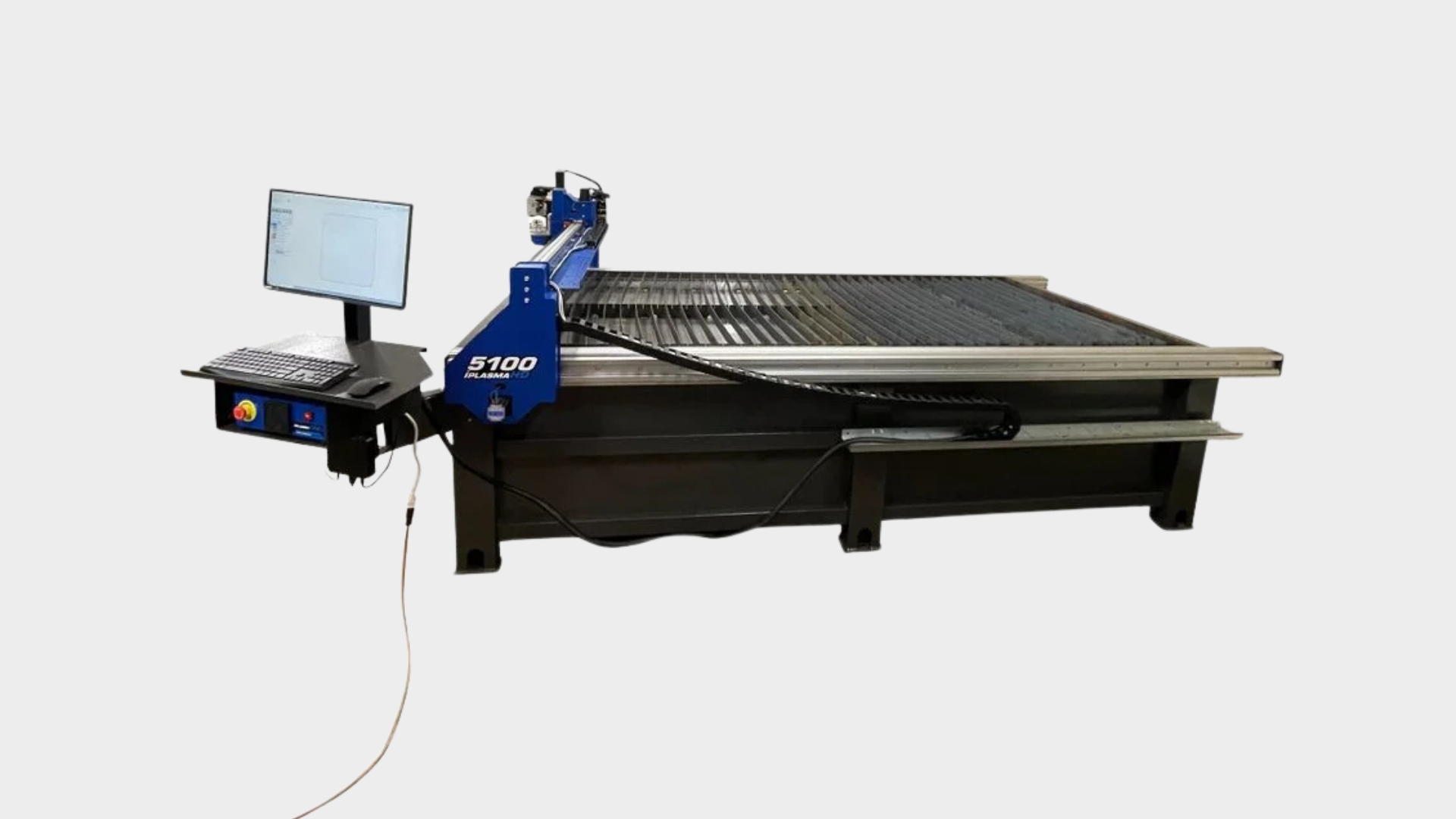

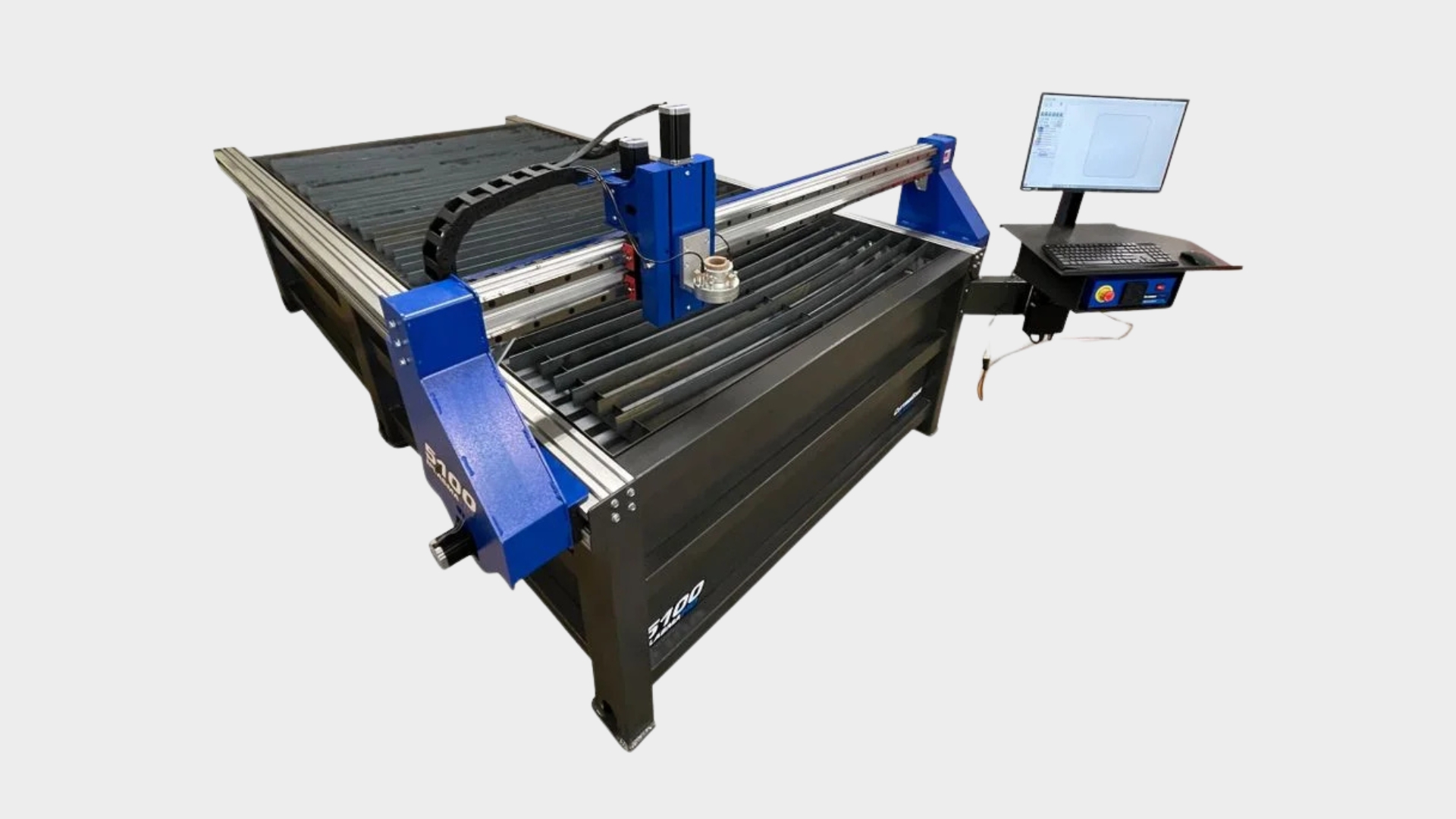

5. iPlasma XTREME 5100 CNC Plasma Table

Price: $17,995

Best for: High-definition cutting, high-volume production, and professional workshops

Features and Build Quality

The iPlasma XTREME 5100 CNC Plasma is designed for workshops with high-demand production needs that require consistent, accurate results. Dual rigid X-axis rails with a rack-and-pinion drive, combined with a dual-drive Y-axis, ensure smooth, reliable motion for every cut. Its fully welded, powder-coated frame provides long-term stability, while the 4" water bed with slats keeps the cutting area cleaner by reducing smoke and debris.

Compatibility with Plasma Cutters: It works with a wide variety of plasma cutters, including customized setups, offering flexibility for different projects.

Included Accessories: The machine comes with a 24" display, Proma or Thermal Dynamics iCNC controller, proximity sensors, and a water table.

Special Features: It offers 8" Z-axis travel for cutting thicker material, collision detection to prevent torch damage, and 5:1 planetary gear reduction units with Nema 34 stepper motors for XY axes to ensure smooth, accurate motion.

Ideal Use Case: This model is perfect for businesses that require HD cutting, repeatable results, and long-term production reliability.

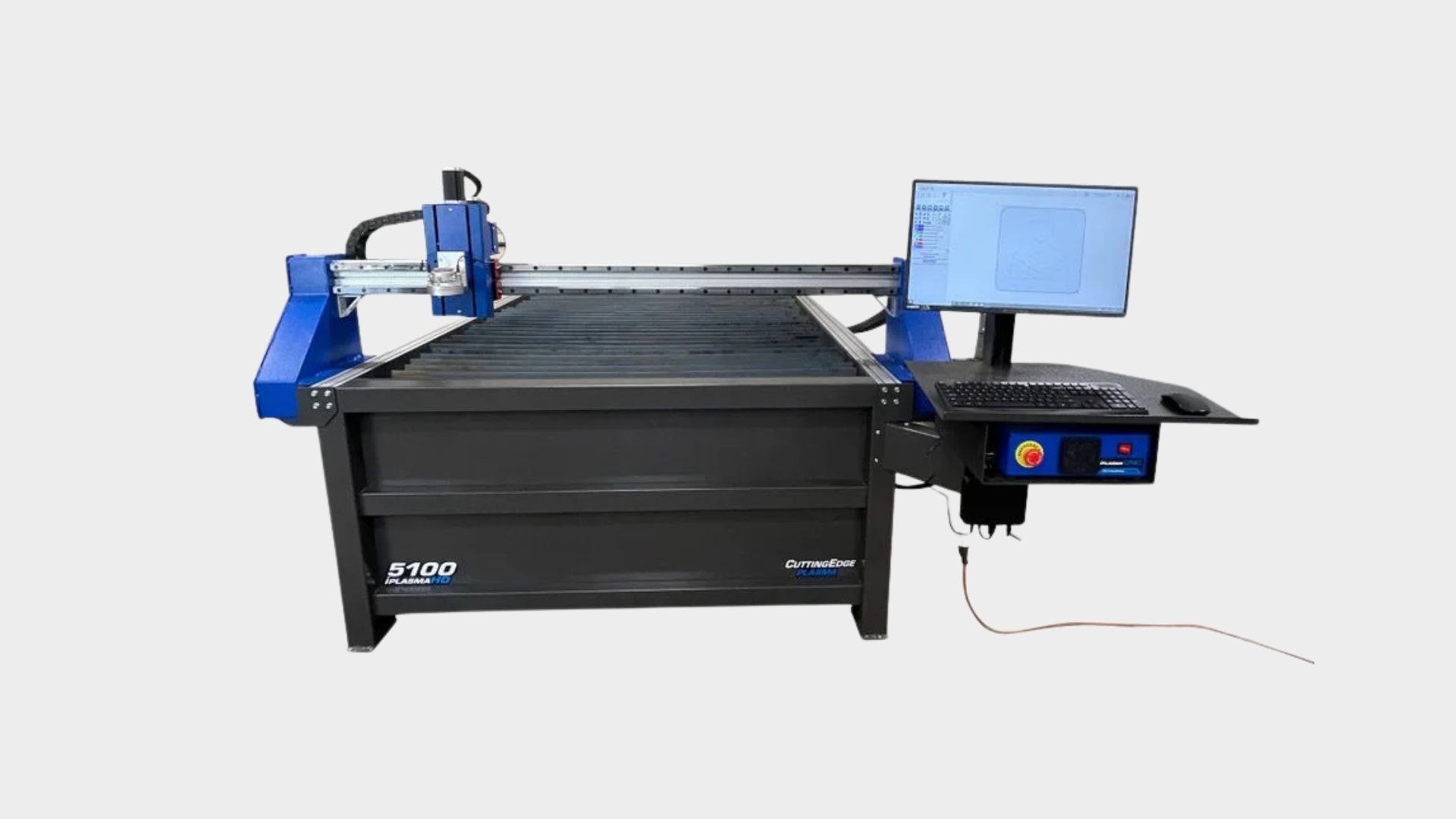

6. iPlasma XTREME 5100 High Definition

Price: $27,000

Best for: Businesses requiring top-end precision and optional high-definition cutting capabilities

Features and Build Quality:

The iPlasma XTREME 5100 High Definition features a fully welded steel frame, dual rigid rails on the X-axis, and dual drives on the Y-axis for smooth, precise motion. Its 4" water bed keeps the cutting area clean, while limited-edition enhancements support high-definition cutting with improved accuracy and efficiency.

Ideal for high-accuracy metalwork, custom fabrication, and detailed projects, this table handles demanding jobs while delivering consistent results.

Compatibility with Plasma Cutters: Works with most plasma cutters and can integrate with supplier-provided systems.

Included Accessories: Includes 24" display, Proma controller, proximity sensors, water bed, and optional HD controller.

Special Features: Advanced controller systems, 8" Z-axis travel for thicker materials, dual-drive Y-axis for smoother motion, automatic torch height adjustment for consistent cuts and reduced rework.

Ideal Use Case: Perfect for fabrication shops that require professional-grade accuracy and a machine capable of managing complex, high-definition cuts.

7. Bosch RA1181 Benchtop Router Table

Price: Varies by retailer

Best for: Woodworking shops that need a reliable all-rounder for multiple routing tasks

Features and Build Quality

Built for long-term stability, the table combines steel and aluminum construction with a spacious surface that supports smooth movement of wood pieces. This setup helps maintain consistent, precise cuts and keeps workflow efficient.

Compatibility with Routers: Compatible with most standard Bosch and other fixed-base routers.

Included Accessories: Comes with a fence, miter gauge, and dust collection port.

Special Features: Adjustable height fence, easy-to-use inserts, and modular expansion options improve cutting accuracy and help prevent errors during material handling.

Ideal Use Case: Perfect for woodworking shops that require a dependable, versatile router table for general-purpose routing.

8. Kreg PRS1045 Precision Router Table System

Price: Varies by retailer

Best for: Woodworkers who need a freestanding table for professional projects

Features and Build Quality

Constructed with high-strength MDF and supported by steel legs, this freestanding system stays stable during operation, minimizing vibration and enabling smoother, more precise cuts throughout your workflow.

Compatibility with Routers: Supports a wide range of plunge and fixed-base routers from major brands.

Included Accessories: Includes a durable fence, dust collection port, and starter pin for angled cuts.

Special Features: The adjustable fence ensures accurate, repeatable cuts, the large surface handles bigger projects efficiently, and the freestanding design keeps the table stable to prevent errors and improve safety.

Ideal Use Case: Ideal for professional shops that need mobility with a stable freestanding router system.

9. Rockler Convertible Benchtop Router Table

Price: Varies by retailer

Best for: Woodworkers who need portability without sacrificing performance

Features and Build Quality

Made from high-quality MDF with steel support brackets, this router table offers sturdy, long-lasting support. It can be used as a benchtop or mounted, providing flexible setup options for small woodworking shops.

Compatibility with Routers: Compatible with most fixed and plunge routers.

Included Accessories: Fence, miter gauge, and dust collection port.

Special Features: Convertible design lets you switch between benchtop and portable use, keeping your workflow flexible while preventing setup errors that could slow production.

Ideal Use Case: Suitable for woodworkers who move between job sites or need flexible workspace options.

10. Ryobi Intermediate Router Table

Price: Varies by retailer

Best for: Hobbyists and intermediate woodworkers needing versatility

Features and Build Quality

Durable MDF and steel construction provide a stable base, keeping your router steady and ensuring smooth, consistent results across all routing tasks.

Compatibility with Routers: Supports a wide range of Ryobi and other standard routers.

Included Accessories: Fence, dust port, and starter pin.

Special Features: Adjustable fence guides material accurately, and universal compatibility lets you handle multiple tasks while preventing misalignment and material damage.

Ideal Use Case: Great for users who need a flexible router table for different types of projects.

After comparing the leading models, it becomes easier to look at the factors that influence long-term performance.

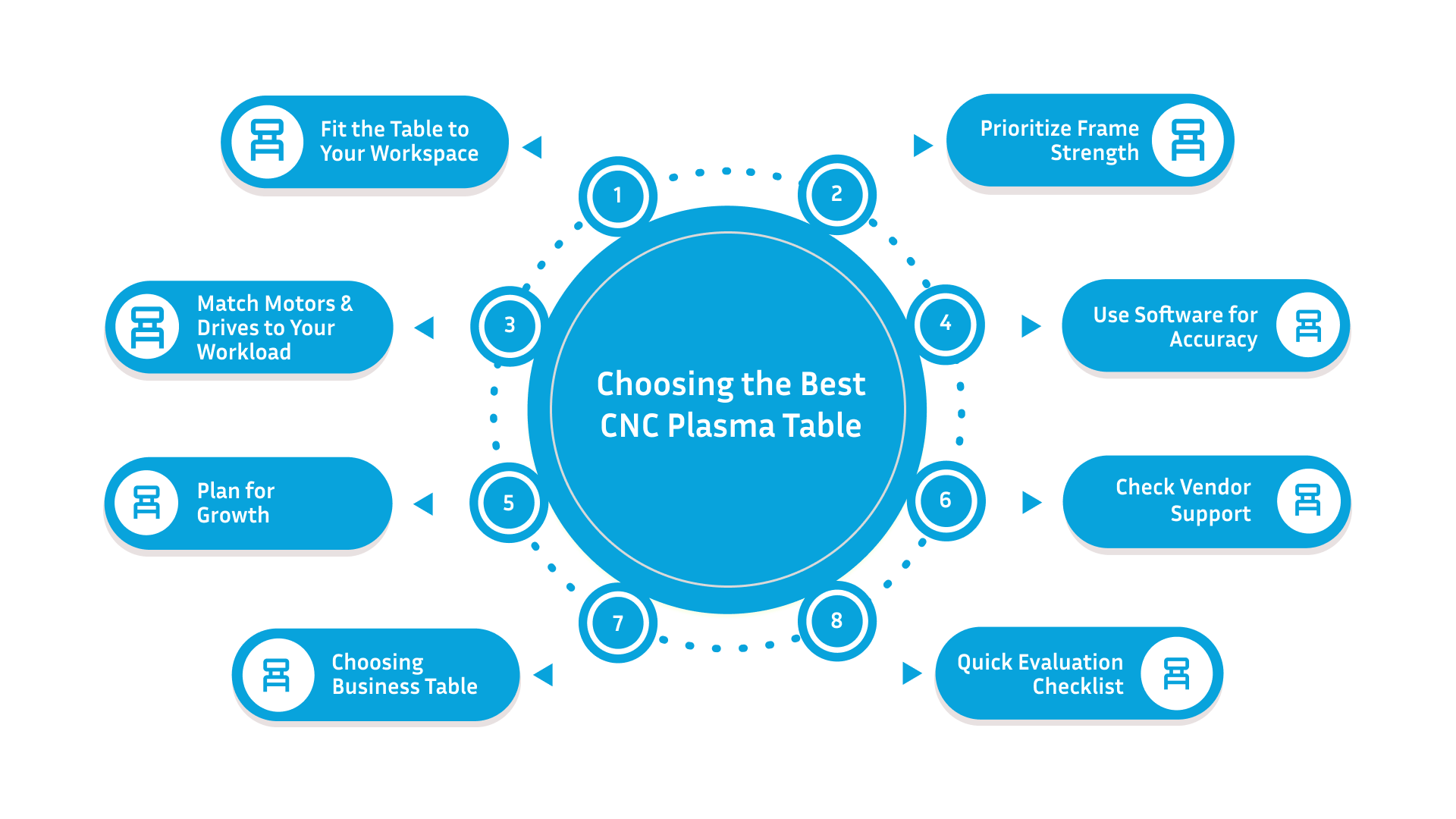

How to Choose the Best CNC Plasma Table for Your Small Business?

Running a small manufacturing business means every decision has an impact. Choosing the right CNC plasma table affects how smoothly your shop operates, how much scrap is produced, and how predictable your costs are.

The table you pick can influence workflow, uptime, and overall productivity. To make the right choice, focus on the factors below that matter most for your operations.

1. Fit the Table to Your Workspace

Start by assessing how the table will fit in your shop. It should allow easy movement of materials and not block other equipment.

A table that suits the sizes of sheets and materials you use most helps production flow smoothly and reduces delays. Thoughtful placement also improves safety and keeps your team efficient.

2. Prioritize Frame Strength and Stability

Once the table fits your workspace, the next point to look at is the strength of its frame. A rigid, well-built frame keeps the surface level during routing, which helps maintain accuracy and reduces the chances of do-overs.

A stable frame also protects the parts that handle most of the work on the table, the router mount, the fence system, and the table surface. When these components stay steady, the router doesn’t shift during cuts, alignment stays consistent, and your team experiences fewer interruptions for adjustments or minor fixes.

Strong construction supports day-to-day reliability, smoother operation, and more predictable output across different types of woodworking jobs.

3. Match Motors and Drives to Your Workload

The motor and drive system should align with your production needs. Smaller motors are sufficient for occasional projects or prototypes, while larger motors handle continuous, high-volume production.

NEMA 23: Suitable for small projects

NEMA 34: Ideal for high-volume production

Reliable drives keep cuts smooth, reduce consumable wear, and prevent unexpected downtime. This makes your output more predictable and keeps schedules on track.

4. Use Software for Accuracy and Efficiency

Software plays a crucial role in accuracy and productivity. Intuitive controls, built-in CAM, and nesting tools simplify job setup and reduce errors. Machines with smart controls, like Proma or iCNC, make operation easier and improve cut accuracy.

With the right software, your team can manage multiple jobs, reduce scrap, and keep production flowing efficiently without unnecessary stress.

5. Plan for Growth

Think about future needs when choosing a table. Modular or high-capacity models let you expand production without replacing the machine. Planning ahead helps manage costs and ensures your investment keeps pace with business growth.

6. Check Vendor Support and Warranty

A responsive vendor like Cutting Edge Plasma can make a big difference. Quick access to parts and guidance helps minimize downtime and keeps operations running smoothly. For smaller teams, reliable support simplifies troubleshooting and maintenance, ensuring you don’t lose valuable production time.

When making your final decision, focus on measurable results. Evaluate uptime, scrap reduction, throughput, cost per unit, and operational flexibility.

These factors show how the table will perform in your daily operations. Choosing the right machine here can make production more efficient and costs more predictable.

7. Choosing the Right Table for Your Business Stage

Starting Out: iPlasma PRO 4400 offers a reliable, budget-friendly entry point, perfect for small shops or low-volume custom jobs.

Growing Business: iPlasma XTREME 4400 balances compact design with industrial stability, handling higher volume production efficiently.

Planning for Long-Term Growth: Our iPlasma XTREME 4800 comes with intuitive software, reducing the learning curve for new operators. We offer durable, reliable construction and competitive pricing, keeping your workshop efficient and within budget.

8. Quick Evaluation Checklist

Factor | Why It Matters | Business Impact |

Table Size | Fits shop & materials | Reduces delays & handling issues |

Frame Rigidity | Maintains alignment | Lowers scrap & maintenance |

Motor/Drive | Matches workload | Supports uptime & cut quality |

Software/Controls | Easy job setup | Reduces errors & scrap |

Scalability | Future growth support | Manages cost per unit |

Vendor Support | Reliable service | Minimizes downtime risk |

This approach helps decision-makers evaluate CNC plasma tables through operational outcomes, focusing on measurable impacts like uptime, scrap reduction, throughput stability, and predictable costs rather than just technical specifications.

Once the core selection factors are in place, it’s useful to understand why many small fabrication shops and metalwork businesses rely on Cutting Edge Plasma systems.

Why Cutting Edge Plasma Works Best for Small-Business CNC Operations?

If you're running a small fabrication shop, metal art business, or custom manufacturing unit, choosing the best CNC plasma table for a small business becomes one of the most critical decisions for productivity and cost control.

The right table helps you deliver cleaner cuts, reduce rework, and keep operating expenses predictable especially when your team handles everything from production to maintenance, and Cutting Edge Plasma delivers the stability, clean operation, and low-maintenance features small businesses rely on every day.

Here’s why small fabrication units, metal art shops, and growing workshops choose Cutting Edge Plasma:

1. Space-Efficient Design: Compact tables fit smaller workshops while still handling custom jobs, metal art, and light production without crowding the floor.

2. Built-In Torch Height Control (THC): THC continuously adjusts the torch height to maintain the ideal distance from the material. This helps protect consumables, reduces scrap, and ensures cleaner cuts, making operations smoother for small teams managing multiple tasks.

3. Waterbed for Cleaner Cutting: A waterbed reduces smoke and dust, making routine cleaning easier and protecting rails and bearings in shops with limited maintenance time.

4. Budget-Friendly Ownership: Manufacturer-direct pricing, long-lasting components, and efficient consumable use make a budget-friendly CNC plasma table a practical choice for growing shops.

5. Anti-Dive Protection: Anti-dive prevents torch crashes during slow feeds or tight corners, helping new operators cut safely and consistently.

6. Simple, Intuitive Software: Built-in CAM tools and real-time G-code handling make daily cutting smoother, ideal for teams where one person manages multiple tasks.

7. Reliable Support Structure: Clear warranty coverage and lifetime support help small shops fix issues quickly without dedicated maintenance staff.

Why does this matter for your business?

The best CNC plasma table for a small business is the one that delivers stable performance, clean operation, and dependable support.

These features keep your production steady, reduce unexpected downtime, and make day-to-day cutting easier for your team.

Conclusion

Selecting the best CNC plasma table for small business helps you maintain steady production, control material loss, and keep operating costs consistent. The right setup also prevents workflow interruptions that can slow orders and add unnecessary pressure on your team.

At Cutting Edge Plasma, we offer CNC systems built to meet these exact requirements, making it easier for small shops to maintain steady output and consistent quality. A clear comparison of the best CNC plasma tables for small businesses gives you the insight you need to choose equipment that supports smooth cutting cycles and predictable performance.

To get clarity on frame design, motion systems, or height-control features, you can reach out to Cutting Edge Plasma today for complete technical information.

FAQs

1. What makes the best CNC plasma table for small business operations?

The best CNC plasma table for small business setups delivers reliable cut quality, steady accuracy, and low operator effort. Look for stable motion control, a rigid frame, and user-friendly software to support predictable daily output.

2. How do I choose between different CNC plasma table models for my shop?

Review a CNC plasma table comparison that covers build strength, torch performance, motion system quality, and software capability. Assessing these factors side-by-side helps you match your purchase with your workload and material needs.

3. Which features matter most in a small business plasma cutting environment?

Consistent torch height control, smooth linear motion, dust management, and easy material handling are crucial. These features help you maintain steady cut performance and avoid avoidable downtime.

4. How does table size impact small business workflows?

Choosing the right table size ensures smooth material movement and reduces rework. A compact footprint works for tighter shops, while a 4x4 or 4x8 table gives more flexibility for larger sheet jobs without slowing operations.

5. How do operating costs vary between CNC plasma table brands?

Operating costs depend on consumable lifespan, cut efficiency, and machine build quality. A well-designed system reduces consumable burn rate, minimizes scrap, and keeps overall expenses predictable for small business owners.