In CNC metal cutting, many small and mid-sized manufacturers struggle with high material waste and inconsistent part quality. These issues often arise from improper design, machine setup, or choosing the wrong cutting technology. This not only leads to higher operational costs but also slows down production, leaving manufacturers with tight margins and delayed orders.

The good news is that with the right design considerations and choosing the proper CNC machine, like selecting a plasma cutter for sheet metal fabrication, these challenges can be minimized, ensuring less waste and improved part quality.

In this blog, we’ll explore the main types of CNC metal-cutting machines, key design strategies, and their applications.

Key Takeaways

CNC metal cutting machines, such as milling, lathe, plasma, and laser cutters, offer high precision and faster production, reducing waste and increasing efficiency for small manufacturers.

Selecting the right machine type is crucial for achieving optimal performance, whether for batch production or complex geometries, ensuring the best results for each job.

Proper design considerations, like standard hole sizes and simple geometries, reduce machining time, prevent tool wear, and minimize costs, ensuring smoother production.

Common challenges like tool wear, programming errors, and machine vibrations can be addressed by using quality tools, checking setup parameters, and following preventive maintenance practices.

CNC machines are used across industries like aerospace, automotive, and energy, offering versatility for fabricators to produce complex parts quickly and efficiently.

What is a CNC Metal Cutting Machine?

A CNC metal cutting machine is a computer‑controlled tool that uses digital instructions to cut, shape, or form metal workpieces with high precision and consistency.

Instead of manual operation, these machines follow a program (usually in the form of G-code / M-code) to control tooling, movement, and cutting parameters, for tasks like milling, turning, plasma cutting, laser cutting, or water‑jet cutting.

This automation allows manufacturers to produce complex geometries, repeatable parts, and accurately cut metal components faster and with less human error compared to traditional manual machining.

The Working Mechanism of CNC Metal Cutting Machines

Knowing how a CNC metal‑cutting machine works helps you pick the right machine, optimize settings, and avoid mistakes. It also helps you plan jobs realistically: if you know how the machine behaves, you can design parts that are easier to manufacture, with fewer rejects and better efficiency.

Design and Programming

The process begins with creating a part design using CAD software. This design is then converted into machine-readable instructions through CAM software, generating G-code (or M-code) that directs the machine on how to move, cut, and shape the material.

Workpiece Setup and Tooling

The metal workpiece is securely mounted on the machine table, and the correct cutting tool (such as a mill, lathe, plasma torch, or laser) is installed, so that the machine is ready for precise machining.

Machine Parameter Setup

The CNC controller loads the generated G-code, and machine parameters like feed rates, spindle speed, and cutting depth are set according to the specifications of the job.

Execution of the Job

The machine follows the programmed instructions, moving the tool (or material in the case of lathes) along the X, Y, and Z axes. In thermal processes like plasma or laser cutting, the machine controls the intensity and positioning of the plasma or laser to cut through metal.

Tool Changes (if necessary)

For complex parts, CNC machines can automatically switch tools mid-process using an automatic tool changer (ATC), reducing downtime and manual intervention.

Material Removal and Shaping

As the machine executes the program, it removes material through cutting, grinding, or burning, shaping the workpiece as per the design, with high precision and repeatability.

Post-Processing

After the cutting process, parts may require additional steps like deburring, cleaning, or surface finishing to achieve the final quality and remove any rough edges or contaminants.

Batch Production and Repeatability

Once the program is tested and verified, it can be used to produce multiple parts with the same specifications, providing high efficiency, consistency, and reduced human error across large production runs.

While the fundamental operating process remains consistent across CNC machines, the specific technology and approach differ depending on your cutting needs.

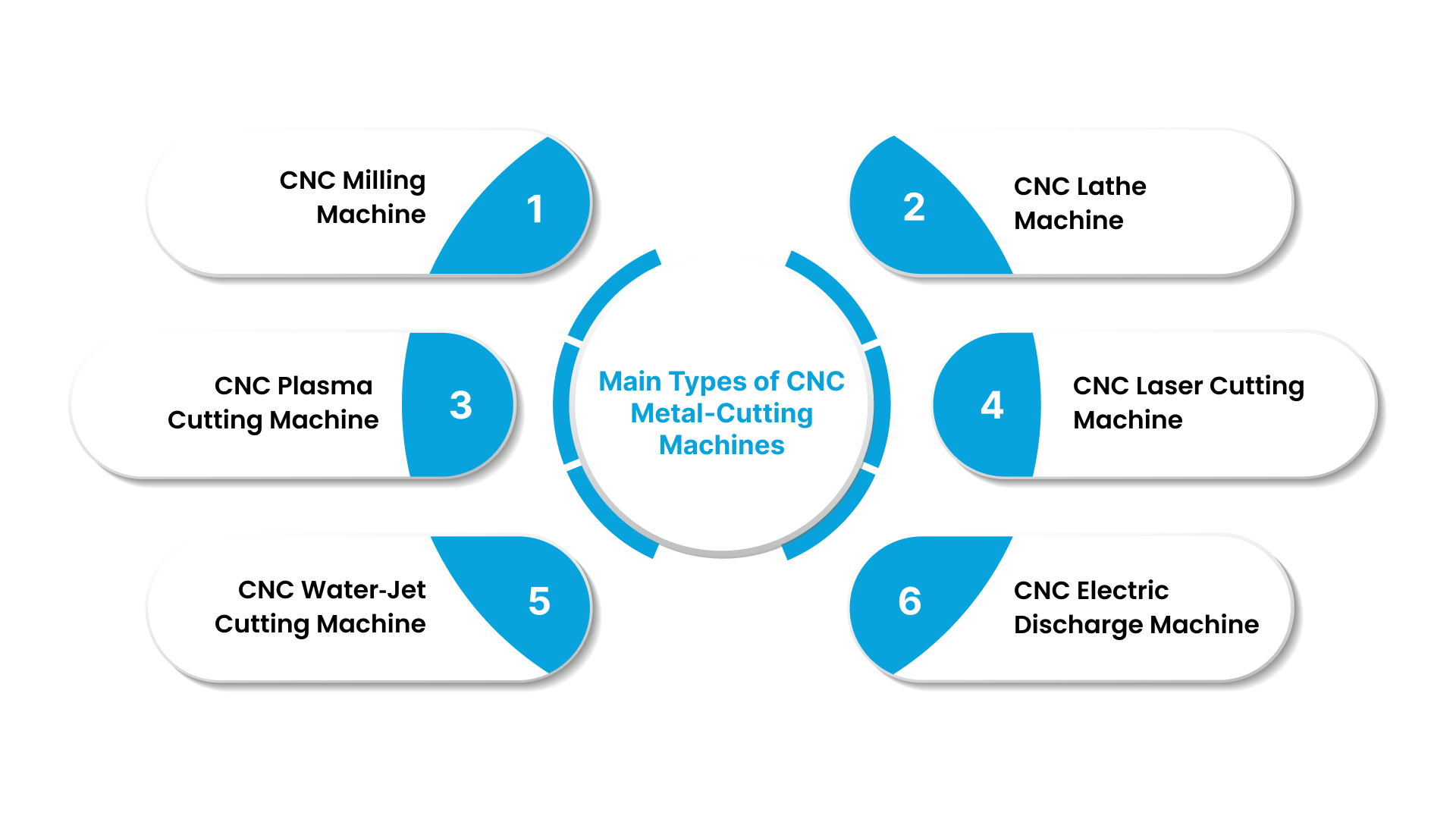

Main Types of CNC Metal‑Cutting Machines

Understanding the different types of CNC metal‑cutting machines helps small and mid‑sized manufacturers choose the right tool for their needs. Whether it's precision cutting with a laser, quick and cost-effective plasma cutting, or detailed work with EDM, selecting the appropriate machine type provides optimal performance.

CNC Milling Machine

A CNC milling machine uses a rotating cutting tool to remove material from a fixed workpiece, shaping it into the desired geometry. The tool moves along multiple axes (usually X, Y, Z; many modern machines support additional axes) to cut complex shapes, contours, grooves, holes, and pockets

Uses

ideal for components requiring precision and complex geometry, such as parts with drilled holes, contours, recesses, pockets, or detailed 3D shapes.

For small and mid‑sized shops, you can manufacture custom parts or small batches with high accuracy without incurring large tooling investments.

CNC Lathe Machine (Turning Machines)

In a CNC lathe, the workpiece rotates while a fixed cutting tool removes material. This is efficient for producing parts that are symmetric around an axis, such as shafts, rods, cylindrical housings, threaded pieces, etc.

Uses

Lathes excel at round or cylindrical components with high precision, such as shafts, bushings, threaded parts, sleeves, basically any part needing rotational symmetry.

For small shops producing metal components like rods, axles, or turned fittings, CNC lathes provide efficient, repeatable production with minimal manual labor.

CNC Plasma Cutting Machine

Plasma cutting uses a high‑temperature ionized gas (plasma) to melt and blow away metal, allowing fast cuts through electrically conductive metals like steel, stainless steel, aluminum, brass, and copper.

Uses

Suitable for cutting large sheet metal or thick metal plates, structural components, and parts where speed and cost‑effectiveness matter more than ultra‑fine precision.

For small or mid‑sized fabrication shops doing metal plate work, structural frames, heavy components, or flat‑sheet fabrication offer a cost‑effective, fast solution.

CNC Laser Cutting Machine

Laser cutting machines focus a highly concentrated, intense laser beam to melt or vaporize material, achieving clean, precise cuts on sheet metal, thin to medium thickness metals, or other materials.

Uses

Compared with plasma cutting, laser cutting delivers higher precision, finer edge quality, a minimal heat‑affected zone, and is better suited for intricate/complex shapes.

For small/mid‑sized shops producing detailed metal parts, decorative metalwork, or thin‑sheet components, laser cutters are ideal when precision and cut quality matter more than cutting thick plates.

CNC Water‑Jet Cutting Machine

Water‑jet cutting uses a high‑pressure stream of water, mixed with abrasive particles, to cut materials. Because it’s a “cold” cutting process (no heat), it avoids heat‑affected zones, warping, or altering material properties.

Uses

It’s ideal for cutting heat‑sensitive metals/materials, composites, or for applications where material properties must remain intact (e.g, no warping, no thermal stress).

For shops handling diverse materials or needing clean cuts on sensitive metals, composites, or mixed materials, water‑jet cutters give versatility, precision, and minimal post‑processing.

CNC Electrical Discharge Machine (EDM)

EDM removes material not by cutting mechanically or thermally, but by using rapid electrical discharges (sparks) between a tool electrode and the workpiece immersed in a dielectric fluid. It erodes material to form precise shapes, cavities, or contours.

Uses

EDM shines when machining very hard metals, difficult alloys, or parts with complex or intricate shapes (e.g., molds, dies, internal cavities, fine detail), often hard or impossible with traditional cutting tools.

This makes EDM valuable for specialized jobs, tool‑and‑die work, and hard‑metal components.

The right machine becomes truly valuable when matched to your industry's demands. Different sectors rely on CNC cutting for specific reasons, each with unique precision, speed, or material requirements.

Key Applications of CNC Metal Cutting Machines in Various Industries

CNC metal cutting machines are widely used across multiple industries for their precision, repeatability, and ability to handle diverse materials. Here’s a breakdown of their key applications:

Aerospace: CNC machines are used to create precise components such as turbine blades, airframes, and engine parts that require tight tolerances.

Automotive: In automotive manufacturing, CNC machines cut parts like engine blocks, suspension components, and custom vehicle parts, supporting both small runs and large-scale production.

Construction and Architecture: CNC machines cut steel beams, frames, and other structural components, ensuring parts fit perfectly in building structures.

Energy and Power Generation: CNC cutting is essential for producing components like turbines and piping systems for power plants, which must withstand high pressures and temperatures.

Metal Fabrication and Custom Manufacturing: Fabrication shops use CNC machines to produce custom parts for various industries, from prototypes to batch production.

Medical Devices: CNC machines are used to manufacture surgical instruments, implants, and other medical devices, where precision and regulatory compliance are key.

Electronics and Consumer Goods: CNC machines cut metal parts for electronics like housings, brackets, and components, ensuring tight fits for proper device functionality.

Understanding where these machines are already making an impact reveals why investing in them makes business sense. The tangible advantages extend beyond individual industries.

Benefits of CNC Metal Cutting Machines

CNC metal cutting machines offer numerous advantages, like high precision and faster production for small and mid-sized manufacturers. Understanding these benefits helps fabricators make the most of their CNC metal investment.

High precision and accuracy: CNC machines cut and shape metal parts to tight tolerances far beyond what manual machining can achieve. This leads to consistent part quality across jobs.

Repeatability and consistency: Once you program the job, the machine can produce the same part repeatedly, ideal for batch production or producing multiple identical components.

Faster production and higher throughput: CNC metal machines automate cutting, drilling, and shaping processes, allowing more parts to be produced in less time, even running continuously without breaks.

Reduced material waste and lower cost: Because cuts are precise and optimized, scrap and rework decrease, which lowers material waste and improves cost‑efficiency.

Flexibility for different jobs and materials: CNC metal‑cutting machines can work with various metals and produce a wide range of shapes, from simple parts to complex geometries, making them suitable for varied production needs.

Lower reliance on highly skilled labor: Because operations are automated and guided by programs, even smaller teams or less‑experienced operators can run complex jobs reliably, reducing labor dependency and associated costs.

The gap between theory and results lies in design. When you account for tool geometry and material behavior during the design phase, you get fewer rejects. On the other hand, if you ignore these factors, even the best machine struggles.

Essential Design Tips for Optimizing CNC Metal Machining

When designing parts for CNC metal machining, attention to detail during the design phase can impact the overall efficiency of the process, reducing costs and minimizing waste. Here are key considerations to keep in mind:

Hole Sizing: Use standard hole sizes wherever possible to avoid the need for custom tooling, which can increase both production time and costs.

Slots and Pockets: Design slots and pockets to be slightly larger than the cutting tool’s diameter. This prevents excessive tool wear and breakage, helping to extend tool life and reduce the need for frequent tool changes.

Unsupported Areas: Limit the use of thin walls or unsupported areas in your design. These can compromise the strength and stability of the part during machining, potentially leading to deformation or breakage.

Other Design Tips for Efficiency and Cost-Effectiveness

Material Selection: Choose materials that not only suit the part’s functional requirements but are also optimized for ease of machining, as it can reduce production time and tooling costs.

Simplifying Geometry: Keep designs simple where possible. Reducing unnecessary complexity helps minimize complexity and costs.

Integrating Features: Whenever possible, integrate multiple features into a single part. This reduces the need for additional components and assembly operations.

Modular Design: Design parts to be modular, allowing for easier replacement or upgrades. Modular designs provide flexibility for future modifications.

Even well-designed parts can falter if execution misses the mark. Tool wear, parameter miscalibration, and maintenance lapses are predictable obstacles, not insurmountable ones.

Common Challenges in CNC Metal Cutting and Solutions on How Manufacturers Can Address Them

Working with CNC metal‑cutting machines brings many advantages, but there are also common pitfalls that small and mid‑sized manufacturers often face. Below are frequent issues, along with solutions grounded in industry practice.

Tool wear and breakage: Over time, cutting tools degrade or break under high cutting forces and heat. This leads to poor surface finish, dimensional errors, and increased tool costs.

Solution: Use high‑quality, coated tools; choose appropriate tool geometry and material for the job; monitor tool life; replace tools proactively before wear causes defects.

Incorrect tool choice or machining parameters: Using the wrong tool type or incorrect spindle speed/feed rate often results in rough cuts, burn marks, tool damage, or part defects.

Solution: Match the tool and cutting conditions (feed, speed, depth) to the material and part geometry. Test on scrap if possible, and adjust parameters for best performance.

Programming or setup errors: Mistakes in CAD/CAM programming, wrong G‑code parameters, or incorrect workpiece setup lead to dimensional inaccuracies or even machine crashes.

Solution: Double‑check designs and toolpaths before production, simulate G‑code when possible, ensure correct workholding, and coordinate setup before starting the run.

Machine vibration or chatter: Vibration, from worn bearings, tool deflection, or unstable clamping, causes poor finish, inaccuracy, and reduced tool life.

Solution: Use rigid tool setups (minimal overhang), ensure secure workpiece clamping, balance tool holders, reduce cutting speed or depth, and maintain machine spindle bearings.

Poor machine maintenance or environmental factors: Lack of regular cleaning, coolant maintenance, or power fluctuations can lead to overheating, component wear, or erratic machine behavior.

Solution: Implement a preventive maintenance schedule — clean chips and debris, check coolant/air supply/filters, monitor power supply quality, and lubricate moving parts.

High initial cost and skilled labor requirement: CNC machines and CAD/CAM software involve upfront investment; skilled operators are required to program and run machines effectively

Solution: Start with versatile, lower‑cost machines suitable for your shop’s typical jobs; invest in operator training; consider incremental upgrades rather than a full-scale setup at once.

Managing these complexities becomes easier with the right equipment partner. Cutting Edge Plasma addresses many of these pain points through thoughtfully engineered features that reduce operator dependency.

How Cutting Edge Plasma Simplifies CNC Metal Cutting for Small Manufacturers

Cutting Edge Plasma offers advanced CNC plasma cutting machines designed for precision, durability, and ease of use, making them ideal for small and mid-sized manufacturers. Their machines help fabricators reduce production time, minimize material waste, and deliver high-quality parts without requiring extensive programming knowledge. Here's how Cutting Edge Plasma supports your CNC cutting needs:

Integrated Torch Height Control (THC): Automatically adjusts the torch height to maintain consistent cutting quality, reducing errors and tool wear.

Anti-Dive Technology: Prevents the torch from dipping during cuts, ensuring clean edges and reducing interruptions.

User-Friendly Controls: Simplifies operation with easy-to-learn interfaces, ideal for small teams or shops with limited technical expertise.

Durable Construction: Built with a fully welded, powder-coated steel frame for long-term reliability, even in demanding production environments.

Conclusion

In CNC metal cutting, choosing the right machine type and understanding key design considerations are crucial for small and mid-sized manufacturers. CNC machines, whether milling, plasma cutting, or laser cutting, offer numerous benefits, including improved precision, reduced waste, and faster production. However, understanding common challenges, such as tool wear and programming errors, and implementing appropriate solutions can help fabricators avoid costly mistakes and optimize efficiency.

Cutting Edge Plasma offers advanced CNC plasma cutting solutions that simplify the cutting process for small manufacturers. Contact us today to learn more about how our CNC plasma cutting machines can help in your operations and improve productivity.

FAQs

What is CNC stainless steel?

CNC stainless steel refers to stainless steel parts or components produced using CNC machining. It offers high durability, corrosion resistance, and precision for various industrial applications.

Is CNC metal good?

Yes, CNC metal machining offers precise cuts, efficient production, and excellent repeatability, making it ideal for high-quality metal parts and reducing material waste.

What are the risks of CNC?

Risks include operator error, machine malfunctions, tool wear, and safety hazards like flying debris. Regular maintenance and training can mitigate these risks.

How long does a CNC last?

A well-maintained CNC machine can last 10-20 years, depending on usage, maintenance, and the machine type. Regular servicing helps extend its lifespan.

How much does a good CNC cost?

The cost of a CNC machine varies based on type and features, but typically ranges from $10,000 to $100,000 or more for high-end models.