Investing in a CNC plasma cutting machine is a major step for any fabrication shop or manufacturing operation, offering dramatic gains in precision, speed, and production capacity.

Yet the wide range of CNC plasma cutting machine prices from entry-level units to premium industrial systems can make the decision overwhelming. This guide breaks down the key pricing tiers, the technical factors that influence cost, and the hidden operational expenses that shape long-term ROI.

Understanding the full cost of ownership ensures your investment delivers lasting, profitable performance.

Key Takeaways

The upfront CNC plasma cutting machine price (Capital Outlay) is secondary to the Total Cost of Ownership (TCO). High-end machines may have better TCO due to reduced consumables wear and superior efficiency.

High-Definition (HD) plasma systems cost significantly more than conventional air plasma but deliver superior cut quality and higher speed, often eliminating the need for expensive secondary finishing (grinding).

Consumables, electrical power, and process gas account for a substantial portion of the running costs. Investing in superior air filtration and operator training (to minimise arc starts) is key to profitability.

The cost of the machine frame, gantry, and motion control (servo vs. stepper) is a direct investment in long-term cutting precision and speed.

Initial Capital Outlay - The Three Price Tiers

The upfront CNC plasma cutting machine price is chiefly determined by three factors: the quality of the motion control system, the power and technology of the plasma source, and the machine's overall size (work envelope).

1. Entry-Level & Hobbyist Machines (£2,000 – £15,000)

These machines are ideal for small workshops, educational institutions, or dedicated hobbyists who require high-quality cuts but only in small batches and with thinner materials.

Target User: Small fabrication shops, artists, and maintenance departments.

Core Capabilities: Typically use a desktop or small table design (e.g., 600mm x 1200mm). They are compatible with low-amperage air plasma cutters (40A to 80A), cutting materials like mild steel up to 10mm or 12mm thick.

Cost Drivers: Utilise stepper motors and basic Torch Height Control (THC) systems. The plasma source is often an entry-level, third-party unit, keeping the CNC plasma cutting machine price at the lower end.

Key Consideration: The cutting duty cycle is often limited, meaning they cannot run continuously for long periods.

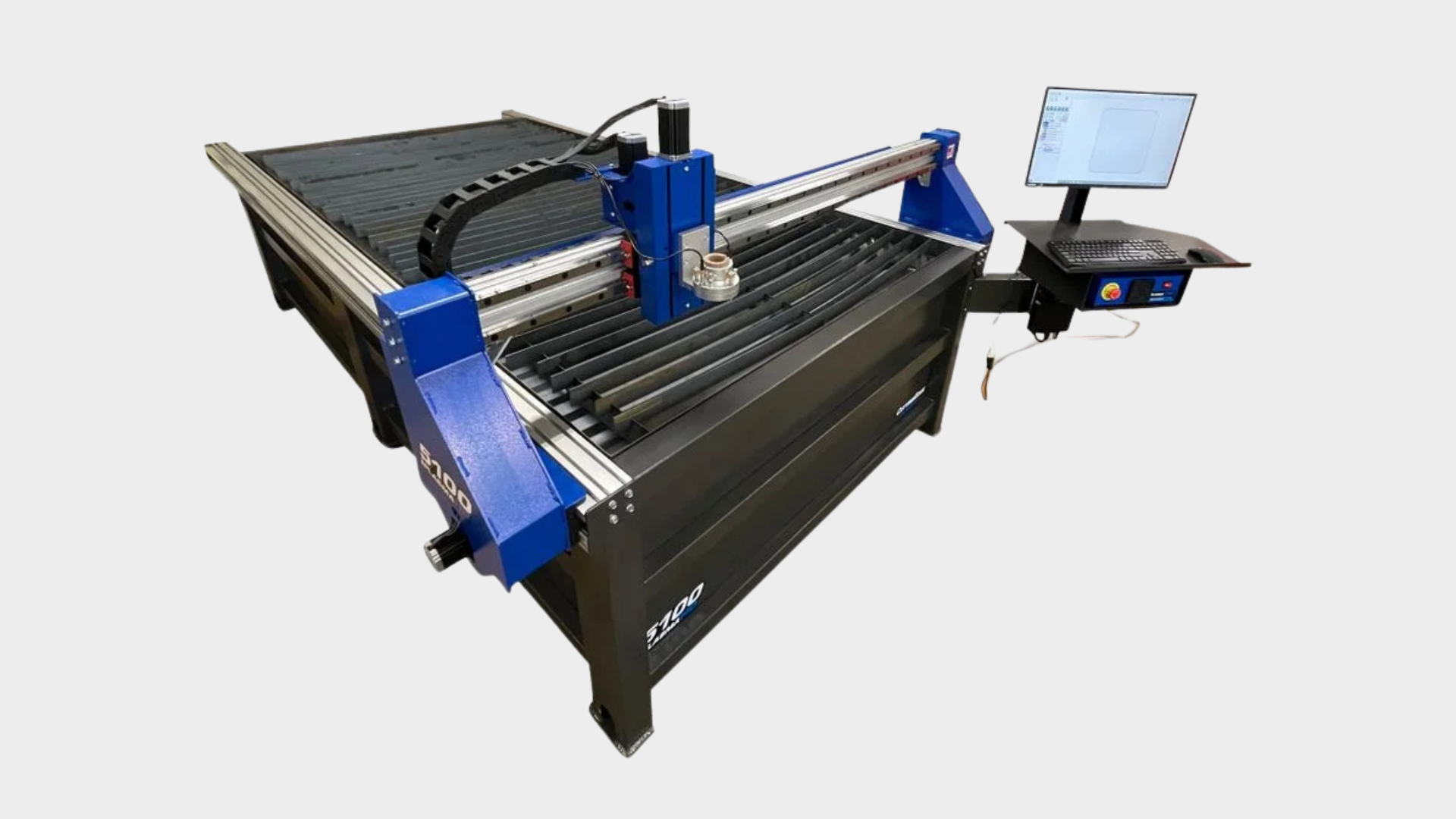

2. Mid-Range Industrial Systems (£20,000 – £80,000)

This is the sweet spot for small-to-medium enterprises (SMEs) that require a substantial upgrade in reliability, cut quality, and throughput.

Target User: Dedicated steel fabricators, job shops, and high-volume automotive aftermarket suppliers.

Core Capabilities: Feature robust, often water-table designs (e.g., 1.5m x 3m) and integrated, branded plasma sources (100A to 200A). They handle production-level cutting of mild steel up to 25mm thickness.

Cost Drivers: Employ servo motors for faster, more accurate motion control and use advanced digital THC. They often include basic nesting software to optimise material usage, justifying the mid-range CNC plasma cutting machine price.

Our Cutting Edge Plasma Industrial Workhorse offers an excellent balance of speed and precision for this tier.

3. Premium High-Definition (HD) Systems (£100,000 – £500,000+)

These gantry-style behemoths are engineered for 24/7 operation, demanding the highest possible cut quality, often rivaling laser cutting on thinner materials.

Target User: Shipbuilding, heavy engineering, oil and gas, and specialised metal service centres.

Core Capabilities: Large work envelopes (up to 4m x 16m), high-amperage (300A+) High-Definition (HD) or X-Definition plasma technology, and multi-axis beveling heads. They can pierce and cut structural steel up to 50mm and edge-start much thicker plates.

Cost Drivers: The plasma power source uses multiple gases (e.g., Oxygen, Nitrogen, Argon-Hydrogen) and complex consoles to achieve perpendicular cuts and superior edge finish. Motion systems use precision rack-and-pinion drives and ultra-stable gantry constructions, significantly increasing the CNC plasma cutting machine price.

Factors Affecting the CNC Plasma Cutting Machine Price

While the tier classification provides a baseline, several technical specifications will cause the price to flex dramatically within any category.

The Plasma Source Technology: Air vs. HD

The biggest single variable in the initial capital expenditure is the plasma power source itself.

Conventional Air Plasma: Uses shop air as the plasma gas. It is simpler, cheaper, and yields a wider kerf (cut width) and more bevel on the edge. This is the standard for entry-level and most mid-range systems.

High-Definition (HD) / X-Definition Plasma: Uses proprietary nozzles and gas mixtures (e.g., F5, H35, N2) with superior cooling. This technology focuses the arc energy tightly, producing narrower kerfs, near-vertical edges, and a surface quality that often eliminates the need for secondary finishing. The cost of a cutting source alone for a premium HD system can often exceed the entire price of a mid-range conventional machine.

Work Envelope Size and Gantry Rigidity

The dimensions of the cutting bed directly influence the machine's construction cost. A 1.5m x 3m table is geometrically simpler and requires less robust support than a massive 4m x 12m gantry system.

Large-Scale Cost: Larger gantries require more powerful motors, heavier, machined rails (often ground within micron tolerances), and a more substantial foundation to maintain accuracy over the cutting span. This ensures that the tolerance deviation is minimal, even when cutting at one corner of a massive plate.

Underwater Tables: Machines equipped with underwater cutting tables for fume and noise suppression add high cost due to the required mechanical lifting system and the reinforced tank structure.

Software and Automation Features

The intelligence that drives the machine is crucial for productivity and forms a significant part of the CNC plasma cutting machine price.

Nesting Software: High-end nesting software (e.g., Lantek, SigmaNEST) can automatically arrange parts on a sheet to minimise scrap material. This software, which can cost thousands of pounds per license, often pays for itself quickly through material savings alone.

Advanced Features: Optional automation features like laser pointers for plate alignment, automatic gas consoles for recipe selection, and automated plate marking tools (e.g., plasma torch scribing) add convenience, speed, and cost.

The Total Cost of Ownership (TCO) - Beyond the Initial Price

The sticker CNC plasma cutting machine price is only the beginning. The long-term profitability of your investment is governed by the running costs, which can quickly dwarf the initial expenditure if not managed correctly.

The Consumables Cost: Electrodes, Nozzles, and Shields

Plasma cutting operates by converting gas into a high-temperature arc using replaceable copper parts. These consumables wear out and must be replaced regularly, directly impacting your cost per metre of cut.

Consumable | Lifespan Factor | Cost Impact |

Electrodes & Nozzles | Primarily driven by the number of arc starts (not arc-on time). Poor operator habits (e.g., excessive starts) increase cost. | Lower amperage systems have cheaper parts, but HD systems have longer-lasting parts that are individually more expensive. |

Shields & Swirl Rings | Affected by piercing thickness and accidental torch crashes. | Replacement is less frequent but is necessary to protect the more costly electrode/nozzle assembly. |

Tip: Always purchase high-quality, genuine consumables. Cheaper, counterfeit parts degrade cut quality, reduce arc stability, and often damage the more expensive torch components, leading to far greater cost in the long run.

Hidden Operating Costs: Power, Gas, and Air Quality

These costs are often underestimated but are vital for accurate job costing:

Electrical Consumption: High-amperage systems require significant three-phase power. A 200A machine consumes considerably more energy per hour than an 80A unit. Power costs typically account for 35%–50% of the total operating expenditure.

Process Gas: For conventional air plasma, the main cost is the air compressor and filtration system. For HD systems, the specialized gases (Nitrogen, Oxygen, Argon-Hydrogen mixes) must be calculated on a per-minute consumption basis. The gas cost increases significantly with material thickness.

Compressed Air Quality: Poor air quality (moisture and oil contamination) dramatically reduces consumable life and destroys the cut quality. Investing in a high-quality dryer, filter, and coalescer system is non-negotiable and adds to the TCO, but saves money on consumables and maintenance.

Maintenance, Spares, and Downtime

Premium systems have a higher upfront cost but often compensate with superior engineering, reducing maintenance and depreciation over the machine's lifecycle.

Depreciation and Service: All capital equipment depreciates. Modern, reliable machines from reputable brands retain better resale value. Factor in an annual service contract, which can range from £1,500 to £5,000 for mid-range systems, to prevent catastrophic failure.

Downtime Cost: The true cost of a machine failure is not the repair bill, but the lost production time. Investing in a machine with a proven track record for reliability and a strong local service presence (like the machines offered by Cutting Edge Plasma) is a crucial step in risk mitigation.

Conclusion

Determining the appropriate CNC plasma cutting machine price for your business is an exercise in meticulous budgeting, not simply choosing the cheapest option. Your decision must be driven by your material thickness, required daily volume, and the acceptable quality of the finished edge.

By weighing the initial capital expense across the three tiers, Entry-Level, Mid-Range, and Premium HD, against the variable long-term costs of consumables, power, and maintenance, you can calculate a precise ROI.

Partnering with a supplier who understands the complexities of these costs, like Cutting Edge Plasma, ensures you receive not just a machine, but a complete, cost-effective cutting solution built for your commercial success.

Ready to invest in a machine that guarantees precision and performance?

Consult with our experts at Cutting Edge Plasma to receive a tailored quote, ensuring your choice of CNC plasma cutting machine price is perfectly aligned with your business's output and budget requirements.

Frequently Asked Questions (FAQs)

Q1. What is the typical lifespan of a CNC plasma cutting machine?

A well-maintained CNC plasma cutting machine from a reputable manufacturer can have a lifespan of 15 to 20 years or more. Longevity is highly dependent on regular preventative maintenance, proper calibration, and the consistent use of high-quality components and consumables.

Q2. How much does a High-Definition (HD) plasma system cost compared to a conventional one?

A premium HD plasma source and gas console can cost anywhere from three to ten times the price of a conventional air plasma source with similar amperage. The higher CNC plasma cutting machine price is justified by the vastly superior edge quality, tighter tolerance, and ability to eliminate secondary processing steps.

Q3. Why are consumables so expensive, and what determines their life?

Consumables are critical, precision-engineered copper components. Their life is primarily determined by the number of arc starts (piercings), not the total cutting time. Higher amperage, thicker materials, and poor quality compressed air will all reduce consumable life.

Q4. Does the size of the cutting bed greatly affect the final CNC plasma cutting machine price?

Yes, dramatically. Moving from a desktop model to a 1.5m x 3m table is a significant jump, but scaling up to a 4m x 12m gantry system increases the cost exponentially. This is due to the required mechanical rigidity, the precision of the gantry components, and the necessity for more powerful motors to move the increased mass accurately.

Q5. What is the biggest hidden cost in running a plasma cutter?

The biggest hidden cost is often the combined expense of consumables and power. In a high-volume industrial setting, consumables must be factored down to a cost per metre of cut, and the electricity usage of both the plasma source and the high-power air compressor must be accurately costed.

Q6. Is it better to buy a cheaper machine and a high-end plasma source?

Generally, yes. The plasma source dictates the cut quality, while the machine's frame and motion system dictate the accuracy and repeatability. A robust, mid-range frame paired with a premium plasma source often delivers the best balance of quality and value, especially for medium-duty fabrication.