If you’ve been researching CNC routers for even five minutes, you’ve probably run into the same confusion everyone faces: Why does one machine cost $1,000 while another pushes $150,000? They look similar in photos, they all promise precision cutting, and every manufacturer claims theirs is “the best value.”

That’s where most get stuck, especially when trying to decide whether a hobby router, a small-shop machine, or a full industrial system is actually worth the investment.

And without clear guidance, it’s easy to overspend, underspend, or choose a router that doesn’t match the materials or workload you really have.

This guide breaks down CNC router cost in simple, practical terms so you know exactly what to expect, what really drives the price, and how to choose the right machine for your workflow, without wasting money on features you don’t need.

Key Takeaways

Clear Price Snapshot: CNC routers range from $1,000–$150,000+, depending on size, spindle power, rigidity, controller quality, and features like ATC or vacuum tables.

Cost Drivers Explained: The biggest factors affecting CNC router cost are table size, motor type (stepper vs servo), software/controller, frame strength, and add-ons — not brand names or marketing claims.

Segment-Specific Pricing: Hobby routers cost $1k–$3.5k, small-shop routers $5k–$18k, and industrial CNC router prices typically fall between $20k–$75k+, depending on production demands.

Total Cost of Ownership Matters: Beyond purchase price, expect added expenses for tooling, software, maintenance, electrical setup, and dust/fume systems, the real long-term cost most blogs skip.

Router vs Plasma for Metal: If you’re cutting steel, stainless, or thicker aluminum, a CNC plasma table (like CEP’s systems) is usually more cost-effective than an industrial router, with lower upfront cost and faster metal throughput.

How Much Does a CNC Router Cost?

If you’re comparing CNC router prices, here’s the fast, no-fluff breakdown:

Hobby CNC routers: $1,000–$3,500

Small-shop CNC routers: $5,000–$18,000 \

Industrial CNC router price: $20,000–$75,000+

Large/custom CNC routers: $80,000–$150,000+

These ranges shift based on table size, spindle power, frame rigidity, drive system (stepper vs servo), controller/software, and optional features like vacuum tables, ATC (automatic tool changers), and enclosures.

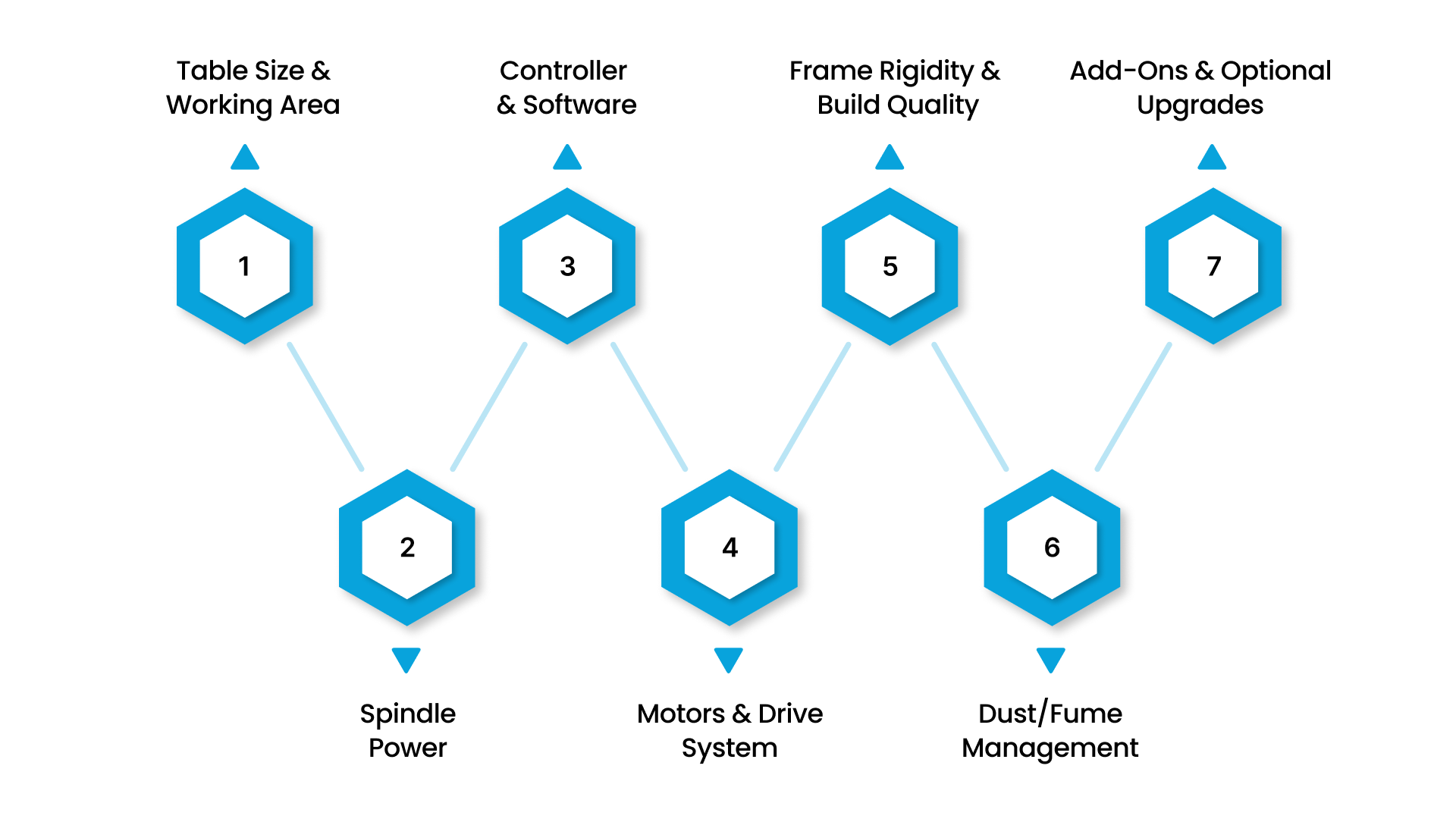

The 7 Key Factors Affecting CNC Router Cost

CNC routers don’t have complicated pricing by accident; their cost is shaped by a handful of core features that directly impact performance, accuracy, and lifespan. Here are the factors that move the price the most.

1. Table Size & Working Area

The larger the cutting area, the more expensive the machine.

A 2x2 or 2x4 hobby router sits at the low end, while 4x8 and 5x10 tables dominate the mid-to-high range.

Bigger tables = heavier frames, larger gantries, more powerful motors → higher cost.

2. Spindle Power (What It Can Actually Cut)

Spindle horsepower determines what materials you can cut and how quickly.

1–2 HP: Wood, plastics, foam

2–4 HP: Hardwood, thicker plastics

5+ HP: Aluminum, composites, production environments

Higher-power spindles require stronger motors, better cooling, and more robust electronics, all of which raise the price.

3. Controller & Software

The controller is the “brain” of the CNC router.

Cheap hobby controllers keep prices low, but limit accuracy, repeatability, and speed.

Industrial-grade controllers add cost because they offer:

Smoother motion

Better interpolation

Higher reliability

Better compatibility with CAM software

For many shops, this is one of the most important investments.

4. Motors & Drive System (Stepper vs Servo)

Motors dramatically influence price and performance.

Stepper motors: Cheap, reliable, good for hobby and light-duty routers

Servo motors: Faster, quieter, more accurate, handle heavy loads, used in industrial routers

The drive system (rack and pinion, belts, ball screws) also affects precision and price.

5. Frame Rigidity & Build Quality

A CNC router is only as good as its frame.

Thicker steel, welded construction, and reinforced gantries cost more, but they deliver:

Less vibration

Cleaner finishes

More accurate cuts

Longer machine life

Budget routers often compromise here, which is why they struggle with heavier materials.

6. Dust/Fume Management

Routers that cut wood or composite materials require:

Dust collectors

Enclosures

Filtration systems

Cutting plastics, MDF, or composites especially demands proper extraction to protect both operators and electronics.

These systems aren’t always included in the base price, but they are essential and add to the overall cost.

7. Add-Ons & Optional Upgrades

These features significantly influence price:

Vacuum table (material hold-down)

Automatic Tool Changer (ATC)

4th axis or rotary attachments

Mist cooling systems

Enclosures

Touch probing

Upgraded rails/gantries

These options can add $1,000 to $30,000+, depending on build quality and complexity.

CNC Router Cost Breakdown by Type

CNC router prices vary widely depending on build quality, motors, work area, and duty cycle. Here’s what each price tier realistically offers and what it doesn’t.

Hobby CNC Router Cost ($1,000–$3,500)

Entry-level routers are built for light workloads and soft materials.

What you get:

2x2 to 2x4 tables

MDF or aluminum frames

Small steppers

Basic hobby controllers (GRBL/Arduino-style)

Light-duty spindles or trim routers

What you don’t get:

High rigidity

Long session cutting

True aluminum capability

Industrial-grade software

Best for: Hobbyists, makers, craft shops, weekend use.

Performance notes: Slowest speeds, lowest accuracy; struggles with anything beyond soft wood.

Typical lifespan: 3–5 years with moderate use.

Small Shop CNC Router Cost ($5,000–$18,000)

A major step up in stability, accuracy, and usable work area.

What you get:

4x4 or 4x8 tables (industry standard for shops)

Steel or hybrid frames

Better steppers or entry-level servos

VFD spindles (2–4 HP)

Recognizable controller/software ecosystems (Mach3/4, UCCNC, Masso)

What you don’t get:

Full automation

High-duty industrial components

True 24/7 production reliability

Best for: Sign shops, furniture makers, cabinet shops, and light aluminum work.

Performance notes: Good accuracy, good speed, great value for growing businesses.

Typical lifespan: 7–10 years with proper maintenance.

Common add-ons: Vacuum tables and dust collection (not usually included).

Industrial CNC Router Price ($20,000–$75,000+)

Built for continuous production, heavier materials, and tight tolerances.

What you get:

4x8, 5x10, or 5x12 work areas

Fully welded steel frames

Servo motors (fast, accurate, quiet)

High-power spindles (5–12 HP)

True industrial controllers (Fanuc, OSAI, Syntec, Masso Elite)

Linear rails, precision ball screws

Optional ATC & vacuum hold-down systems

What you don’t get:

Cheap components

Lightweight construction

Best for: Manufacturers, production facilities, composite shops, boat builders.

Performance notes: High speed, excellent repeatability, reliable multi-shift use.

Typical lifespan: 10–20 years in production environments.

Custom / Large-Format CNC Router Price ($80,000–$150,000+)

Built for specialized industries and high-output operations.

What you get:

Oversized beds (5x10, 5x12, 6x12, 10x20+)

Multi-head machines

4th/5th axis capability

High-end servo drives

Full enclosures

Heavy automation

Best for: Aerospace, marine, composites, and industrial fabrication.

Performance notes: Maximum rigidity, fastest cut speeds, complex multi-axis motion.

Typical lifespan: 15–25+ years.

Here’s how each CNC router price tier stacks up in terms of accuracy, materials, features, and real-world use.”

Budget Range | Accuracy | Materials Supported | Key Features | Speed | Best For |

|---|---|---|---|---|---|

$1,000–$3,500 (Hobby) | Low–Medium | Softwood, MDF, plastics, foam | Light frames, basic steppers, hobby controllers | Slow | DIY users, hobby shops, light crafting |

$5,000–$18,000 (Small Shop) | Medium–High | Wood, plastics, light aluminum | Steel frames, stronger spindles, better controllers | Medium–Fast | Sign shops, furniture makers, and small fabrication shops |

$20,000–$75,000+ (Industrial) | High | Wood, plastics, aluminum, composites | Servo motors, ATC options, welded frames, pro controllers | Fast | Production shops, manufacturing lines, precision work |

$80,000–$150,000+ (Large/Custom) | Very High | Composites, thick aluminum, specialty materials | Large beds, multi-head, 4th/5th axis, full automation | Very Fast | Aerospace, marine, and large-scale manufacturing |

At this point, you probably have a good idea which CNC router tier fits your budget and workflow. But here’s something most of us don’t realize: routers and plasma tables aren’t interchangeable, especially in metal fabrication.

Let’s take a moment to clear up when a CNC router makes sense… and when a CNC plasma table is actually the better, more affordable tool.

CNC Router vs CNC Plasma for Metal Fabrication

Many buyers comparing CNC router costs are ultimately trying to cut metal, and that’s where router capabilities and plasma capabilities diverge sharply.

Understanding the difference can save thousands of dollars and help you choose the right tool for your workflow.

CNC Routers Excel in Wood, Plastics, Foam & Composites

Routers use a high-speed spindle to carve material mechanically. They shine in environments where clean edges, fine detail, and consistent chip removal matter.

Best materials for routers:

Hardwood

Plywood/MDF

Plastics (Acrylic, HDPE, PVC)

Foam

Composite panels

For these substrates, CNC routers offer precision, smooth finishes, and low operating costs.

Routers Can Cut Aluminum, But Have Limits

With the right tooling and settings, a router can cut aluminum sheet and plate.

However, cutting steel or stainless steel pushes routers beyond their intended design:

Spindles lack torque for harder metals

Heat buildup becomes a major issue

Bits wear out quickly

Feed rates must be drastically reduced

Vibrations affect accuracy and tool life

This is why industrial routers capable of routine metal cutting are extremely expensive, often $40,000–$75,000+.

Plasma Is Faster, More Affordable & Better for Metal

For steel, stainless steel, and aluminum plate, plasma is purpose-built to deliver:

Higher cutting speeds

Lower per-part cost

Minimal tool wear

Clean cuts on thick material

Lower machine cost compared to industrial metal-capable routers

Plasma tables excel in metal fabrication shops where throughput, cost efficiency, and thickness capability matter more than ultra-fine edge detail.

For metal fabrication applications, CNC plasma tables, like those from Cutting Edge Plasma, often cost less than industrial routers while delivering higher productivity on steel, stainless, and aluminum.

CEP machines are engineered specifically for metal workflows, which is why many shops find them a better fit than high-cost industrial routers when cutting anything beyond thin aluminum.

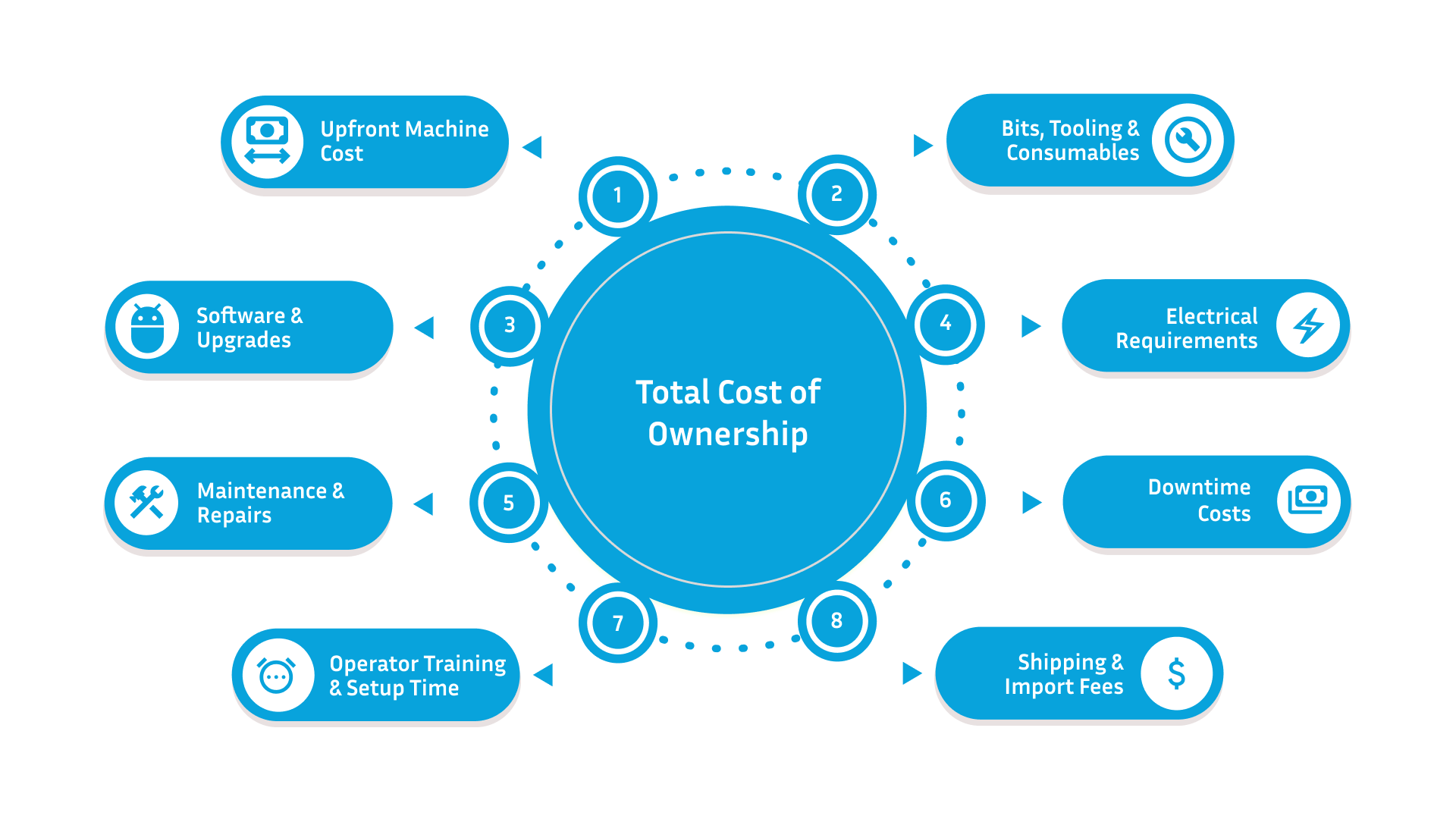

Total Cost of Ownership (TCO)

The true cost of owning a CNC router includes tooling, software, power requirements, maintenance, and even downtime. Failing to consider these factors underestimates the budget by 20–40%.

Here’s the complete picture, clearly broken down.

1. Upfront Machine Cost

The base price depends on size, motors, spindle, controller, and rigidity.

This is your biggest single expense, but not the only one.

2. Bits, Tooling & Consumables

Routers rely heavily on tooling.

Typical recurring costs:

End mills & bits

Collets & tool holders

Spoilboards

Lubrication/misting systems

Shops often spend $50–$300/month in tooling, depending on workload.

3. Software & Upgrades

Beyond the included controller, you may need:

CAD/CAM software (Fusion 360, VCarve, Aspire, SolidWorks CAM)

Paid upgrades for post processors

Annual licensing or subscription renewals

This adds $200–$2,000/year, depending on complexity.

4. Electrical Requirements

Many routers require:

220V circuits

Dedicated breakers

Potential panel upgrades

Surge protection

Electrical setup can cost $200–$2,500, depending on the shop.

5. Maintenance & Repairs

Essential for uptime and long machine life.

Includes:

Rail lubrication

Belt/ball screw adjustments

Spindle bearings

Motor/controller replacements

Expect $300–$2,000/year depending on use.

6. Downtime Costs

This is the silent expense most guides never mention.

Downtime affects:

Production schedules

Delivery timelines

Labor efficiency

Customer satisfaction

Industrial shops feel this the most.

A $60 bearing failure can cost $600+ in delayed output.

7. Operator Training & Setup Time

Whether in-house or external:

CAM workflow learning curve

Toolpath strategy

Material fixturing

Maintenance routines

Training can take hours to weeks, which is still a cost, even if indirect.

8. Shipping & Import Fees

Especially relevant for global buyers.

Costs include:

Freight

Crating

Duties

Customs

Local transport & unloading

This often adds 5–15% to the purchase price.

Mini Table: One-Time vs Recurring Costs

Cost Type | One-Time | Recurring |

|---|---|---|

Machine Purchase | ✔ | — |

Electrical Setup | ✔ | — |

Shipping/Import | ✔ | — |

Tooling & Bits | — | ✔ |

Software Licenses | — | ✔ |

Maintenance | — | ✔ |

Repairs | — | ✔ |

Operator Training | ✔ / Ongoing | ✔ (if staff changes) |

Downtime Losses | — | ✔ |

How to Choose the Right CNC Router (Simple 4-Step Decision Guide)

With so many price ranges and machine types, choosing the right CNC router can feel overwhelming. This quick 4-step framework helps you identify the right machine fast—without second-guessing your budget or buying something you’ll outgrow.

Step 1: What Materials Do You Cut?

This is the most important question.

Wood, MDF, plastics, foam, composites → Choose a CNC router.

Aluminum (light/moderate volumes) → Router or plasma, depending on finish needs.

Steel, stainless, thick aluminum → Plasma, not a router.

If your workflow involves metal fabrication even occasionally, you may not need an industrial router at all. A CNC plasma table will:

Cost less upfront

Cut thicker metal

Work faster

Require fewer consumables

Material defines the machine more than any other factor.

Step 2: What Working Area Do You Need?

Buying too small forces constant tiling and flipping. Buying too large an increase the cost unnecessarily.

General guidelines:

2x2 or 2x4: Hobby/DIY

4x4: Light commercial

4x8 or 5x10: Most professional shops

5x12+: Industrial production or large-format work

Pick a size that fits your largest regular job, not occasional oversized projects.

Step 3: What Level of Precision Matters?

Your accuracy needs determine the motor and drive system:

Basic detail → Stepper motors

Affordable, reliable, ideal for woodworking and signage.

High precision / long production runs → Servo motors

Fast, smooth, quiet, better repeatability, used in industrial machines.

If you routinely cut parts that must fit together perfectly, or work in composites/aluminum servo-driven routers are worth the investment.

Step 4: What’s Your Actual Budget?

Once you know your material, size, and precision needs, the price range becomes easy to define.

To avoid overpaying (or underbuying), always request multiple CNC router equipment quotes that list:

What’s included

What’s optional

Controller type

Motor type

Spindle specs

Warranty

Training/support

Lead time

Shipping/installation fees

Well-structured quotes let you compare machines apples-to-apples instead of guessing.

Pro Tip: A lower upfront price doesn’t always mean lower cost. Check TCO (tooling, software, dust systems, downtime) before deciding.

CEP Advantage (Only If You’re Cutting Metal)

If your work includes steel, stainless, thicker aluminum, brackets, gussets, or metal signage, a CNC plasma table is often the smarter, more affordable tool, and that’s where Cutting Edge Plasma comes in.

When a Router Isn’t the Right Tool → Plasma Is

Industrial routers capable of cutting metal reliably are large, expensive, and require powerful spindles, servo systems, and rigid frames. They easily reach $40,000–$75,000+.

For metal-focused workflows, plasma delivers:

Lower machine cost

Faster cut speeds

Minimal tooling expenses

Better performance on steel and stainless

Thicker cutting capacity

If metal is your priority, a router becomes the wrong investment.

CEP Specializes in CNC Machines Built for Metal Cutting

Cutting Edge Plasma designs CNC systems specifically for metal fabrication, not wood routing. Their machines focus on the factors that matter most when cutting steel, stainless, and aluminum plate:

Clean edges

Consistent torch height

Stable motion

Minimal slag and rework

High repeatability

These are the exact areas where plasma outperforms routers in metal applications.

Why CEP CNC Plasma Tables Stand Out

1. Industrial-Grade Rigidity

Heavy, welded steel frames eliminate vibration, producing cleaner edges and accurate parts even on thick plate.

2. Integrated Torch Height Control (THC)

Maintains perfect standoff distance across the sheet, critical for minimizing dross and ensuring consistent cut quality.

3. Anti-Dive Technology

Prevents the torch from dropping during slow moves (corners, holes), reducing gouging and eliminating bottom-edge burr buildup.

4. MyPlasma Motion Control System

Advanced CNC software with smooth interpolation, refined cornering, and precise lead-ins/lead-outs for cleaner results.

5. Standard Waterbed for Cleaner Cuts

Reduces heat distortion, suppresses fumes, minimizes slag formation, and significantly cuts down finishing time.

Cleaner Edges → Less Finishing → Lower Long-Term Cost

A cleaner cut means:

Less grinding

Less consumable use

Less operator fatigue

Faster production flow

Fewer rejected parts

Lower total cost of ownership

For metal fabricators comparing CNC router cost to plasma cost, CEP machines often deliver higher productivity at a lower price point.

Ready to See What You Can Save?

Explore how much cleaner and faster metal cutting can be:

Request a Quote to get exact pricing for your table size and workflow

Conclusion

Choosing the right CNC router comes down to understanding your materials, accuracy needs, and real long-term costs, not just the sticker price. Whether you’re buying your first machine or upgrading to handle bigger workloads, the smartest investment is the one that matches your workflow without locking you into unnecessary features or hidden expenses.

And if your work leans toward metal fabrication, it’s worth remembering that a CNC plasma table often delivers better performance, lower operating costs, and cleaner results than an industrial router.

That’s where Cutting Edge Plasma stands out: purpose-built systems designed for stable motion, consistent torch height, and clean edges that reduce finishing time.

Curious how CEP machines perform in real shops?

Read the Reviews and see what fabricators are saying before you decide.

FAQs

1. How much does a CNC router cost?

CNC routers typically cost $1,000–$150,000+, depending on size, spindle power, motor type, rigidity, controller quality, and optional features like ATC or vacuum tables. Most small business machines fall in the $5,000–$18,000 range.

2. Why do CNC routers have such a wide price range?

Prices vary because routers differ in table size, motor technology (stepper vs servo), spindle horsepower, frame rigidity, controller/software, and automation features. Industrial-grade components increase accuracy, lifespan, and duty cycle—raising cost.

3. Is a CNC router worth it for small businesses?

Yes. A CNC router can dramatically improve efficiency, consistency, and production capability for woodworking, sign-making, and light aluminum work. Small shops typically see ROI within 6–18 months, depending on workload and materials.

4. How much does it cost to maintain a CNC router?

Expect to spend $300–$2,000 per year on maintenance, tooling, and minor repairs. This includes bits, collets, spoilboards, lubrication, cleaning, and occasional spindle or motor service.

5. Should I buy a CNC router or a CNC plasma table for metal?

For steel, stainless, and thick aluminum, a CNC plasma table is more affordable, faster, and better suited than a router. Use a CNC router primarily for wood, plastic, foam, and composite materials.

6. How long does a CNC router last?

Lifespan depends on duty cycle and build quality:

Hobby routers: 3–5 years

Small-shop routers: 7–10 years

Industrial routers: 10–20+ years

Proper maintenance significantly extends longevity.