Hypertherm plasma systems are known for their reliability, but even the best equipment needs routine maintenance to maintain stable arc quality, predictable cut performance, and consistent uptime.

When core components aren’t inspected on time or small issues go unnoticed, it can lead to unstable arcs, inconsistent edges, higher scrap, and unplanned downtime on the shop floor. Understanding where issues start and how to correct them helps keep production steady and prevents workflow interruptions.

This guide provides practical, operator-friendly steps for inspecting, cleaning, and performing Hypertherm plasma cutter repair, so your team can maintain safe operation, consistent cut quality, and reliable throughput.

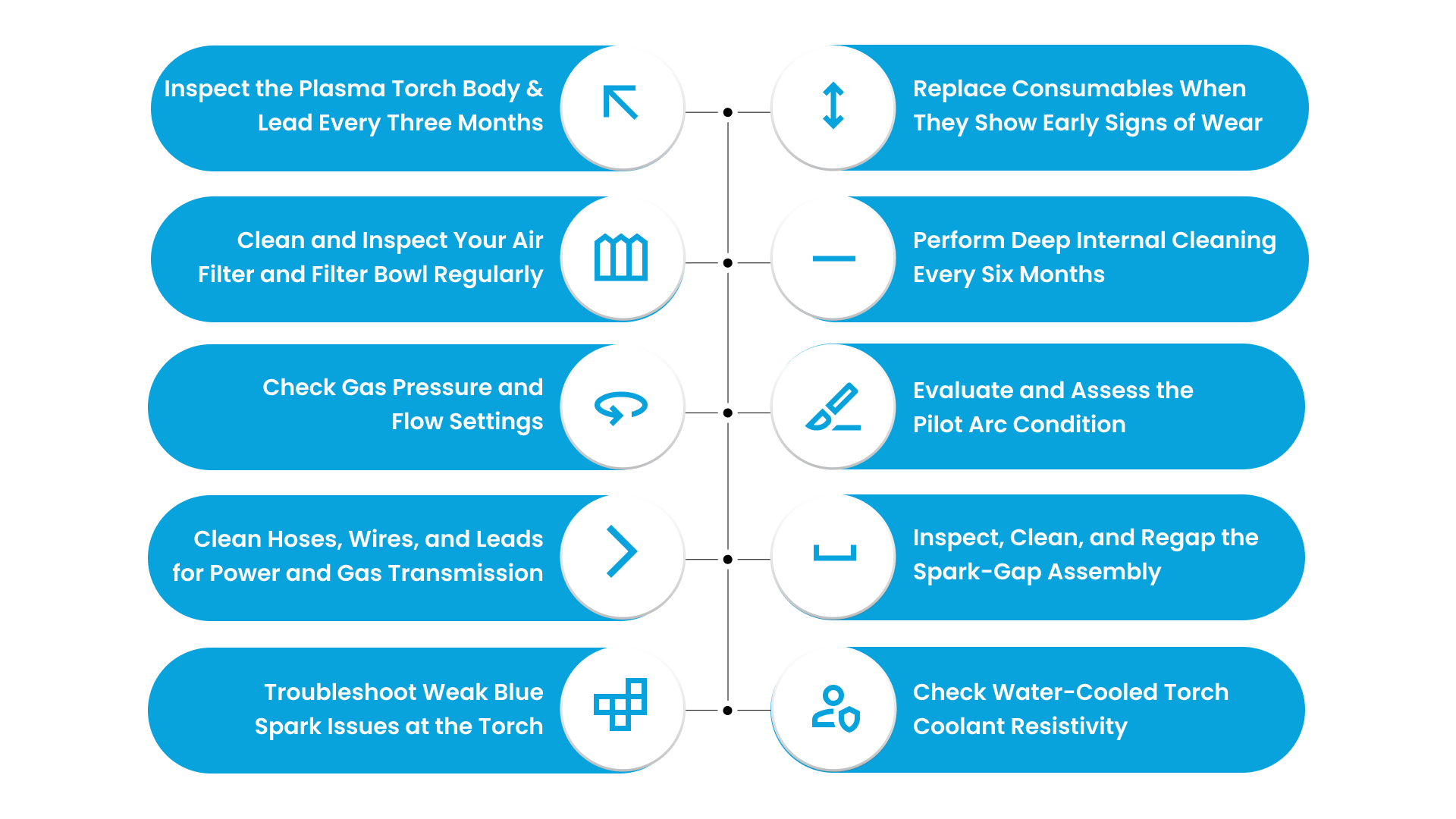

Key Takeaways

Consistent torch inspection improves arc stability and reduces scrap caused by worn components, supporting smoother Hypertherm plasma cutter repair and maintenance.

Replacing consumables at the right time prevents cut variation and nozzle damage, which makes Hypertherm plasma cutter repair simpler and more predictable.

Clean air supply and filter maintenance help maintain predictable cut performance.

Deep internal cleaning reduces contamination-related downtime and supports steady operation.

Correct pressure settings, pilot arc checks, and spark-gap maintenance improve overall reliability.

Why Regular Hypertherm Maintenance Matters for Reliable Production?

Keeping your Hypertherm plasma cutter in top shape isn’t just about equipment, it’s about keeping production smooth and predictable. For optimal performance, Hypertherm plasma cutters rely on clean airflow, well-maintained consumables, and reliable internal and electrical components.

When you follow a regular maintenance routine, your team can:

Cut unplanned downtime: Regular checks prevent torch faults and arc instability that can slow production.

Keep cut quality consistent: Clean components and timely consumable replacement ensure smooth, uniform edges across all jobs.

Reduce operating costs: Avoid excessive wear on consumables and critical parts, saving on replacements and scrap.

Improves first-pass accuracy: Fewer errors mean less rework and smoother workflow, keeping throughput steady.

Ensure smooth and efficient operations with Cutting Edge Plasm’s structured maintenance routines and expert guidance.

Our ange of plasma systems, including Hypertherm Powermax125, Powermax105, Powermax85, Powermax65, and Powermax45, built for accurate, clean, and consistent cutting. Using these solutions together supports steady throughput, predictable results, and minimized unplanned downtime, keeping your workflow dependable and efficient.

With regular maintenance, your Hypertherm system stays predictable, safe, and cost-efficient. It makes troubleshooting easier, helps your team avoid surprises, and keeps production running smoothly.

10 Practical Steps To Maintain Hypertherm Plasma Cutter Repair and Troubleshooting

Hypertherm plasma cutters are powerful tools that help you achieve precise, clean cuts in metal fabrication. But even the most reliable equipment can run into issues if not maintained properly. The key to keeping your cutter performing consistently lies in simple, routine checks and maintenance.

Each step below explains not just what to do for your hypertherm plasma cutter repair, but why it matters and how it impacts your workflow.

1. Inspect the Plasma Torch Body and Lead Every Three Months

The torch is the most critical part of your plasma cutter, so any damage or wear can immediately affect performance. Regular inspection helps prevent leaks, unstable arcs, and premature consumable wear.

What to Do:

Check O-rings for cracks, deformation, or hardening because damaged O-rings can cause air leaks.

Inspect the torch body for heat marks, carbon buildup, or visible wear, which may indicate overheating or stress.

Examine the torch lead for fraying, cracks, or insulation damage that could affect electrical performance.

Why It Matters:

Keeping the torch clean and intact ensures stable arc performance, reduces air leaks, and supports consistent cut quality. Using genuine Hypertherm components helps maintain compatibility and reduces the risk of damage. Regular inspection also sets the stage for smooth consumable performance and predictable cutting results.

2. Replace Consumables When They Show Early Signs of Wear

Consumables like electrodes, nozzles, and shield caps directly influence cut quality and overall system efficiency. Using them beyond their lifespan can increase scrap and slow down production.

What to Look For:

Look for pitting or irregular wear on electrodes, as this can disrupt arc consistency.

Check nozzle openings for blockages or deformation, which affects gas flow and cut precision.

Inspect shield caps for burn marks or deformation that might reduce protective function.

Monitor arc initiation to ensure it remains consistent and reliable.

Why It Matters:

Replacing consumables on time maintains steady arc performance, reduces scrap, and prevents unplanned downtime.

Genuine Hypertherm consumables deliver predictable results, helping operators maintain reliability and efficiency. This step naturally connects with torch inspection since worn consumables often indicate upstream wear in the torch itself.

3. Clean and Inspect Your Air Filter and Filter Bowl Regularly

A stable air supply is essential for reliable plasma cutting. Moisture, dust, or oil can disrupt the arc and damage consumables, so regular cleaning is crucial.

Steps to Follow:

Drain any accumulated moisture, which can interfere with airflow and arc stability.

Remove dust, oil, or debris from the filter housing to maintain proper airflow.

Inspect the filter bowl for cracks or wear that could allow contaminants into the system.

Why It Matters:

Clean air ensures steady arcs, prevents overheating, and reduces consumable failures. Performing this step regularly keeps cut quality stable and helps prevent unexpected production issues.

It also supports the next step, internal cleaning, by reducing the amount of dust and debris circulating inside the cutter.

4. Perform Deep Internal Cleaning Every Six Months

Internal contamination, such as dust or carbon buildup, can cause misfires and erratic arcs. And Cutting Edge Plasma machines are designed for easier internal access, making this step faster and more effective.

Focus Areas:

Clean all airflow paths inside the cutter to ensure that gas delivery remains consistent and the arc stays stable.

Remove dust and debris from chambers and other internal areas to prevent disruptions in the cutting process.

Inspect all connectors and remove any carbon deposits that could interfere with electrical performance or gas flow.

Why It Matters:

Regular internal cleaning ensures consistent airflow, reliable arc ignition, and fewer interruptions. This step protects critical components and supports smooth, long-term operation, making troubleshooting less frequent and easier.

5. Check Gas Pressure and Flow Settings

Correct gas pressure and flow are essential for forming a stable, predictable arc. Without proper settings, misfires and uneven cuts can occur.

What to Inspect:

Verify the line pressure and regulator settings to ensure that the gas supply is consistent and steady, which helps maintain reliable arc performance.

Check all hoses for kinks, blockages, or leaks because any restriction can reduce gas delivery and destabilize the arc.

Observe the gas flow at the torch to confirm that it is smooth and uninterrupted, ensuring consistent cutting conditions throughout the operation.

Why It Matters:

Maintaining correct gas settings reduces misfires, keeps cuts uniform, and extends consumable life.

Pressure-related problems are a common cause of downtime, so checking these regularly ensures predictable operation. This also connects to evaluating the pilot arc since correct gas flow directly affects arc stability.

6. Evaluate and Assess the Pilot Arc Condition

The pilot arc is what starts every cut, so stability here is critical. A weak or inconsistent pilot arc can slow production and increase scrap.

What to Watch For:

Monitor for delayed arc ignition, as this can indicate upstream issues such as worn consumables or irregular gas flow.

Observe weak or flickering arcs, which can compromise cut quality and lead to inconsistent results.

Check for arcs that cut out mid-job, since this can result in defective parts and increased material waste.

Why It Matters:

A stable pilot arc ensures reliable starts, reduces scrap from failed cuts, and keeps operations smooth during longer jobs.

Pilot arc issues often indicate upstream problems, such as worn consumables or incorrect gas flow, so resolving them early prevents bigger issues.

7. Clean Hoses, Wires, and Leads for Power and Gas Transmission

Hoses and leads are responsible for carrying both power and gas to the torch. If they become contaminated or damaged, airflow can be restricted, and electrical performance can become unstable, which directly affects cutting quality.

Steps to Follow:

Wipe down all hoses, wires, and leads to remove dust, debris, and any residues that may have accumulated over time and it helps maintain consistent gas flow and electrical conductivity.

Carefully inspect hoses and leads for cracks, stiffness, or burn marks, as these issues can compromise performance or cause sudden failures during operation.

Make sure that all connections are secure, clean, and free from corrosion to prevent intermittent power loss or gas leaks that could disrupt cutting.

Why It Matters:

Keeping hoses, wires, and leads clean and intact ensures stable airflow and reliable power delivery to the torch. This reduces the risk of unexpected stoppages, protects sensitive components, and supports smooth, uninterrupted operation.

Additionally, this step complements spark-gap and pilot arc maintenance, since both rely on a consistent supply of power and gas to function properly.

8. Inspect, Clean, and Regap the Spark-Gap Assembly

The spark-gap assembly is essential for initiating the pilot arc. Dirt or misalignment can cause misfires and inconsistent cuts.

What to Check:

Remove any debris from the electrodes to ensure that the spark functions properly during each arc initiation.

Confirm that the gap distance is correctly set, as this ensures consistent and reliable arc starts every time.

Inspect the surfaces of the electrodes for signs of wear or damage that could negatively impact performance.

Why It Matters:

A well-maintained spark-gap reduces misfires, stabilizes arcs, and minimizes operator intervention. By ensuring the spark-gap works properly, you make pilot arc checks more effective and reduce unnecessary downtime.

9. Troubleshoot Weak Blue Spark Issues at the Torch

Weak blue sparks often indicate upstream problems. Check consumables, air pressure, and electrical connections promptly to prevent downtime. Using Cutting Edge Plasma’s Hypertherm parts ensures compatibility and reliable troubleshooting.

Common Causes:

Worn or damaged electrodes can affect spark formation and reduce arc reliability.

Incorrect air pressure or inconsistent gas flow can prevent the spark from forming correctly.

Faulty wiring or poor electrical connections may interrupt power delivery to the torch.

A dirty or misaligned spark-gap can disrupt proper pilot arc initiation.

Why It Matters:

Fixing spark issues promptly ensures predictable arc starts, improves cut quality, and reduces scrap.

Early attention avoids complex repairs later and supports the effectiveness of previous maintenance steps, like consumable replacement and torch inspection.

10. Check Water-Cooled Torch Coolant Resistivity (If Applicable)

For water-cooled torches, maintaining proper coolant quality is essential. Contaminated or degraded coolant can cause overheating, reduce performance, and increase wear.

What to Inspect:

Check the coolant color and clarity to identify any signs of contamination, such as discoloration or cloudiness, which can indicate impurities or bacterial growth.

Look for signs of degradation or debris in the coolant, as these can clog internal passages and reduce the effectiveness of cooling.

Verify that the coolant has the correct resistivity levels to ensure stable temperature control and prevent electrical issues within the torch.

Why It Matters:

Maintaining proper coolant prevents overheating, reduces torch wear, and supports long-term reliability. This final step protects the most sensitive components of your cutter and ensures all other maintenance efforts work together to keep operations smooth.

By following these 10 steps, you can keep your Hypertherm plasma cutter performing reliably, minimize downtime, and maintain high-quality cuts.

How Cutting Edge Plasma Helps Maintain Reliable Hypertherm Performance?

If you want a Hypertherm plasma cutter that’s easier to maintain and troubleshoot, Cutting Edge Plasma is worth considering. Our approach focuses on stable cutting performance, fewer operational interruptions, and long-term reliability.

Here’s how our setup supports maintenance-ready operations:

1. Proven Expertise

We have extensive experience supporting plasma systems. For plant managers and maintenance teams, this ensures dependable access to parts, guidance, and troubleshooting know-how.

And we have wide range of plasma systems like Hypertherm Powermax125, Powermax105, Powermax85, Powermax65, and Powermax45. This ensures dependable access to parts, guidance, and troubleshooting know-how.

2. Structured Troubleshooting Protocols

We provide clear, step-by-step troubleshooting guides for Hypertherm cutters. From inspecting torches and consumables to evaluating gas flow and pilot arc conditions, these protocols help identify issues early, reducing unplanned downtime.

3. Genuine Replacement Parts

Using authentic Hypertherm components such as torches, consumables, and filters, reduces wear, prevents misfires, and keeps cutters performing at optimal levels.

4. Optimized Cleaning and Maintenance Practices

We emphasize regular filter inspections, hose and lead cleaning, and internal system checks. This minimizes arc instability, prevents contamination, and ensures consistent cut quality.

5. Intuitive Support Resources

Our comprehensive guides, training resources, and lifetime tech support make it easier for maintenance teams to act quickly when issues arise, avoiding prolonged stoppages.

6. Operational Safety Features

Features like pilot arc monitoring and torch protection systems help prevent damage during cuts, which lowers consumable usage and reduces maintenance stress.

Why it matters:

Reliable Hypertherm plasma performance isn’t just about cutting accuracy, it’s about keeping production steady and maintenance predictable. By combining genuine parts, structured troubleshooting, and expert support, Cutting Edge Plasma helps reduce downtime, extend cutter life, and maintain consistent operational efficiency.

Ensure stable performance and easier maintenance cycles with Cutting Edge Plasma solutions designed for high-demand fabrication and production environments.

Conclusion

Taking a little time for proper maintenance goes a long way in keeping your Hypertherm plasma cutter reliable and efficient. Regular torch inspections, timely consumable replacement, clean air systems, and careful troubleshooting all work together to prevent unexpected stops, reduce scrap, and protect your investment.

With Cutting Edge Plasma, you also get the benefit of clear maintenance checklists, genuine replacement parts, and expert guidance, making Hypertherm plasma cutter repair easier and more predictable. This support helps your team keep the cutter performing at its best and maintain smooth operations throughout every production shift.

Contact Cutting Edge Plasma today to explore tools, services, and expert support that make Hypertherm plasma cutter repair straightforward while ensuring your operations run efficiently and reliably.

FAQs

1. What are the first checks to run during Hypertherm plasma cutter troubleshooting?

Start with airflow, consumable condition, torch connections, and power supply stability. These quick checks help you pinpoint the source of cut quality issues or unexpected shutdowns.

2. How do I know when my Hypertherm plasma cutter needs professional repair?

Frequent misfires, inconsistent arc starts, unusual noises, or visible damage to cables or torches usually signal that the machine needs a technician’s attention.

3. Which components wear out the fastest in a Hypertherm plasma cutter?

Electrodes, nozzles, swirl rings, and retaining caps take the most heat load. Regular replacement keeps arc performance steady and protects internal hardware.

4. How can routine care reduce the need for Hypertherm plasma cutter repair?

Maintaining clean air filters, checking gas pressure, replacing consumables on schedule, and inspecting torch leads help prevent stress on internal components and extend machine life.

5. What should operators do when cut quality drops suddenly?

Review consumable condition, verify air pressure, inspect grounding, and confirm the material settings. These steps resolve most day-to-day Hypertherm plasma cutter troubleshooting issues without stopping production.